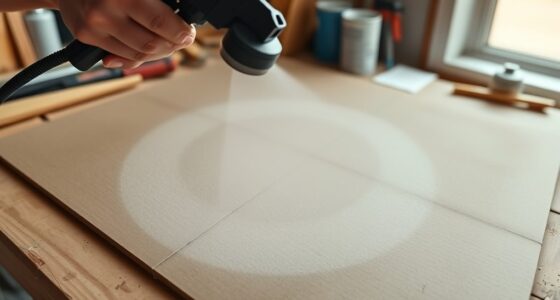

Airless paint sprayers are the go-to equipment for achieving a perfect paint job, thanks to their effective design and precise accuracy. With components like a pump, nozzle, hose, gun, tank, and motor, it is essential to regularly maintain these sprayers to guarantee they work at their best.

By cleaning filters, using the prime valve to remove air bubbles, and inspecting and cleaning the manifold and nozzle, users can achieve consistent paint flow and a smooth finish.

This article explores the essential components and provides detailed maintenance tips for airless paint sprayers.

Key Takeaways

- Regularly clean and maintain filters for smooth paint flow and to prevent clogs.

- Use the prime valve to easily prime the pump and remove air bubbles for improved performance and reduced maintenance.

- Inspect and clean the manifold regularly to control paint flow and pressure, and troubleshoot any leaks or uneven spray patterns.

- Clean and inspect the nozzle regularly, replace worn-out or damaged nozzles, and maintain proper spray pattern and paint flow for desired results.

Components of the Airless Paint Sprayer

The airless paint sprayer consists of several components that work together to deliver high-pressure paint for precise application. These components include the pump, nozzle, hose, gun, tank, and motor.

The pump is responsible for pressurizing the paint and delivering it to the nozzle. The nozzle, on the other hand, delivers a focused stream of paint with surgical accuracy.

To transport the paint from the sprayer to the surface being painted, the hose comes into play. It serves as the conduit for the paint, ensuring a smooth and efficient flow.

For precise control over the paint flow, the gun is used. It allows the user to adjust the flow rate and direction, ensuring accuracy during application.

The tank plays a crucial role in storing the paint before it is sprayed. This ensures a continuous supply of paint and minimizes interruptions during the painting process.

Lastly, the motor drives the pump for paint flow. It provides the necessary power to maintain the high-pressure required for efficient paint delivery.

Overall, this paint delivery system ensures efficient and controlled paint flow, allowing for precise and accurate application on various surfaces.

Maintenance and Troubleshooting

Regularly cleaning and maintaining the filters ensures smooth paint flow and prevents clogs in the airless paint sprayer. It is important to troubleshoot common paint flow issues and uneven spray patterns to achieve optimal results. One common issue is decreased spray pattern or paint spitting, which can be caused by dirty filters. Cleaning the filters using appropriate solutions will help restore proper paint flow. Another factor to consider is the nozzle and spray pattern. Regularly inspecting and cleaning the nozzle, as well as choosing the right nozzle size and pressure settings, will ensure an even and consistent spray pattern. Clogging in the nozzle can be avoided by proper cleaning and maintenance, using high-quality paint, and spraying at the correct pressure. By following these maintenance and troubleshooting tips, users can maximize the performance of their airless paint sprayer.

| Common paint flow issues | Troubleshooting uneven spray patterns |

|---|---|

| Decreased spray pattern | Clean filters |

| Paint spitting | Inspect and clean nozzle |

| Clogging in the nozzle | Choose the right nozzle size and settings |

| Uneven spray pattern | Properly clean and maintain the sprayer motor |

Filter Maintenance

To ensure consistent paint flow and prevent clogs, users should regularly clean and maintain the filters in their airless paint sprayer.

Cleaning techniques for filters depend on the type of filter being used. Mesh filters can be cleaned by rinsing them with water or a cleaning solution, while tip filters can be cleaned by soaking them in a cleaning solution.

It is important to thoroughly dry the filters before reattaching them to the sprayer.

In some cases, filters may become damaged or worn out and will need to be replaced. It is recommended to check the filters regularly for signs of wear and replace them as needed.

Proper filter maintenance is essential for maintaining optimal paint flow and preventing damage to internal components.

Prime Valve

Users can easily prime the pump of an airless paint sprayer by turning the prime valve counterclockwise and pulling the trigger to draw paint and remove air bubbles. This cleaning procedure ensures optimal performance and prevents clogs.

The prime valve is an essential component that allows for easy priming of the pump. To troubleshoot any issues with the valve, users should regularly clean it for optimal performance.

By attaching the paint hose, turning on the sprayer, and switching the valve back to the spray position after priming, users can ensure smooth and consistent spraying.

The prime valve is an important part of the airless paint sprayer maintenance routine, and following the proper cleaning procedure and troubleshooting tips will result in improved performance and longevity of the equipment.

Nozzle and Spray Pattern

Inspecting and cleaning the nozzle regularly ensures optimal performance and a desired spray pattern for an airless paint sprayer. Cleaning techniques for the nozzle involve removing any paint buildup or debris that may affect the spray pattern. This can be done by soaking the nozzle in a cleaning solution and using a small brush or toothpick to gently scrape away any residue. It is important to be careful not to damage the nozzle while cleaning.

Nozzle selection is also crucial for achieving the desired spray pattern. Different nozzle sizes and shapes produce different spray patterns, such as a narrow fan for detailed work or a wider fan for larger areas. Consider the type of paint being used and the surface being sprayed when choosing the appropriate nozzle.

Proper cleaning techniques and correct nozzle selection will ensure consistent and professional results with an airless paint sprayer.

Pump Issues and Troubleshooting

The user can troubleshoot pump issues by checking for clogs or blockages, inspecting the piston for wear or damage, and ensuring proper lubrication and tight connections.

Pump maintenance is essential to ensure the airless paint sprayer functions properly. Clogs or blockages can disrupt the paint flow, leading to uneven spray patterns or decreased performance.

Regularly inspecting the piston for wear or damage is crucial for the longevity of the pump. If the piston is worn or damaged, it may need to be replaced to maintain optimal functionality.

Additionally, ensuring proper lubrication and tight connections is necessary to prevent leaks and maintain smooth paint flow.

Motor Maintenance

Properly maintaining the motor is crucial for optimal performance of the airless paint sprayer. To prevent motor overheating and ensure its longevity, there are some essential maintenance steps to follow.

-

Lubrication: Regularly lubricate the motor’s moving parts with the manufacturer’s recommended lubricant. This reduces friction and heat buildup, extending the motor’s lifespan.

-

Cleanliness: Keep the motor clean from dust, debris, and excess paint. Use a soft brush or cloth to remove any buildup that could hinder the motor’s performance or cause overheating.

-

Ventilation: Ensure proper ventilation for the motor to dissipate heat. Avoid covering or blocking the motor’s vents, as this could lead to overheating and potential damage.

-

Inspection: Regularly inspect the motor for any signs of wear or damage. Replace any worn-out or damaged components promptly to prevent further issues and maintain optimal motor performance.

Safety Precautions for Airless Paint Sprayers

When using an airless paint sprayer, it is important to follow safety precautions to ensure a safe and effective painting experience.

Safety guidelines for airless paint sprayers include proper handling of the gun and nozzle. It is essential to hold the gun securely and firmly, maintaining a steady grip throughout the painting process. The nozzle should be pointed away from oneself and others to prevent accidental injuries.

It is also crucial to wear protective gear such as safety glasses, gloves, and a respirator to protect against paint fumes and overspray. Additionally, it is recommended to work in a well-ventilated area and keep flammable materials away from the spray area.

Following these safety guidelines will help ensure a safe and successful painting project.

Frequently Asked Questions

How Do I Choose the Right Nozzle for My Airless Paint Sprayer?

When choosing the right nozzle for an airless paint sprayer, several factors should be considered.

These include the desired spray pattern, flow rate, and project requirements.

The size of the nozzle and pressure settings also play a crucial role in determining the spray pattern and paint delivery. It is important to adjust these factors to achieve the desired finish.

Additionally, proper cleaning, using high-quality paint, and spraying at the appropriate pressure can prevent clogging in the nozzle and ensure optimal paint flow.

What Are Some Common Issues That Can Occur With the Pump of an Airless Paint Sprayer?

Common pump issues can occur with an airless paint sprayer, causing disruptions in paint flow and performance. Troubleshooting pump problems is crucial for smooth operation.

Clogs or blockages in the pump can lead to decreased pressure and uneven spray patterns. Inspecting the piston for wear or damage, ensuring proper lubrication, and checking for tight connections are important steps in resolving pump issues.

Regular maintenance and cleaning of the pump components are essential for optimal paint flow and desired results.

How Often Should I Clean and Inspect the Manifold of My Airless Paint Sprayer?

The manifold of an airless paint sprayer should be cleaned and inspected regularly to ensure optimal performance. The cleaning frequency depends on the usage and condition of the sprayer, but it is generally recommended to clean and inspect the manifold after every painting session or at least once a month.

This helps to control paint flow and pressure, identify any leaks or uneven spray patterns, and troubleshoot potential issues. Regular maintenance of the manifold is crucial for achieving desired results and prolonging the lifespan of the sprayer.

Can I Use Any Type of Paint With an Airless Paint Sprayer, or Are There Specific Types That Work Best?

Airless paint sprayers can be used with a variety of paint types, but there are specific types that work best.

Water-based paints, oil-based paints, latex paints, and acrylic paints are all compatible with airless paint sprayers. Each type of paint has its own pros and cons when used with these sprayers.

Water-based paints are easy to clean up, but may require more coats for full coverage. Oil-based paints provide a durable finish, but have longer drying times. Latex paints offer quick drying and low odor, but may not adhere well to certain surfaces. Acrylic paints are versatile and offer good adhesion, but can be more expensive.

It is important to choose the right type of paint for your specific project and follow the manufacturer’s recommendations for optimal performance.

Are There Any Special Safety Precautions I Should Take When Using an Airless Paint Sprayer Indoors?

Special safety precautions should be taken when using an airless paint sprayer indoors. Proper ventilation is crucial to ensure good indoor air quality and prevent the buildup of paint fumes. It is recommended to wear protective gear such as goggles, gloves, and a respirator to protect against any potential hazards.

Additionally, it is important to cover and protect surrounding areas to prevent any accidental paint overspray. Following these precautions will help create a safe and controlled painting environment indoors.

Conclusion

In conclusion, proper maintenance and care of the essential components of an airless paint sprayer are crucial for achieving optimal performance and results.

Regular filter maintenance ensures consistent paint flow and a smooth finish, while the use of the prime valve facilitates easy priming of the pump.

Cleaning and inspecting the nozzle and spray pattern are necessary to prevent clogging and achieve the desired finish.

One example of the importance of maintenance is a case study where a painter neglected to clean the nozzle, resulting in uneven paint application and costly rework.

By following maintenance tips and adhering to safety precautions, users can maximize the lifespan and efficiency of their airless paint sprayers.

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.