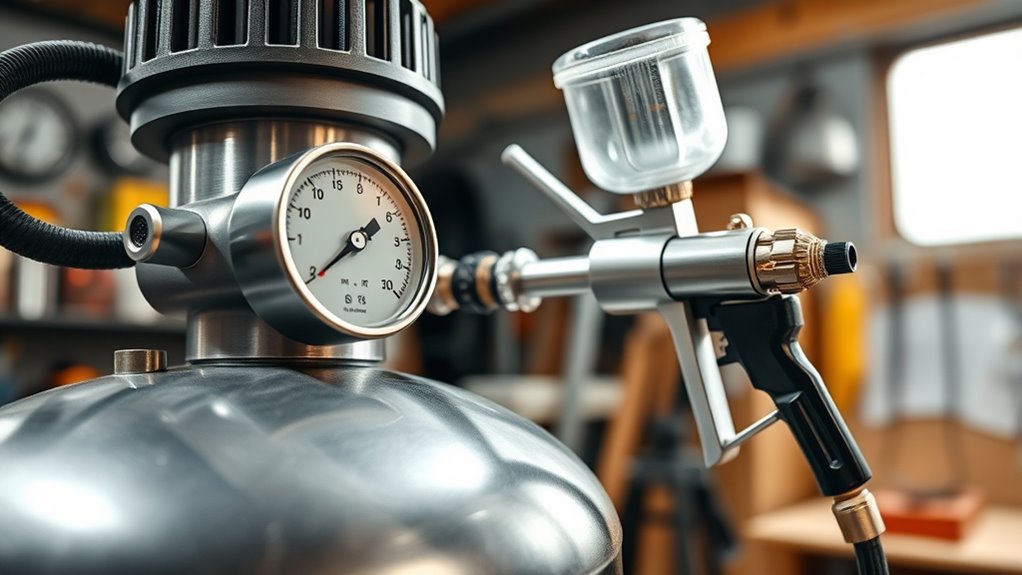

To find the right air compressor for your paint spray gun, check its CFM and PSI requirements, usually found in the product specs. A compressor with at least 10-15 CFM at 90 PSI works well for most spray guns, but larger projects may need more. Keep in mind tank size and portability based on your workspace. Understanding these details helps guarantee smooth operation and a professional finish—more tips to optimize your setup come next.

Key Takeaways

- Check the spray gun’s recommended CFM and PSI specifications for proper compressor matching.

- Select a compressor with a CFM rating slightly above the spray gun’s requirements for better performance.

- Ensure the compressor tank size supports continuous spraying, typically 20 gallons or more for longer projects.

- Consider noise level and portability based on your workspace environment and project mobility needs.

- Match compressor specifications to your project scope and nozzle size to ensure consistent, high-quality finishes.

Understanding the Airflow Requirements of Your Spray Gun

To effectively choose the right air compressor for your paint spray gun, you need to understand its airflow requirements. Air quality is vital because contaminants like moisture or oil can ruin your finish, so select a compressor with good filtration to maintain clean, dry air. Additionally, consider noise levels; a quieter compressor helps create a safer, more comfortable workspace, especially for prolonged use. High noise levels can cause fatigue and distraction, reducing your work quality. Confirm the compressor supplies consistent airflow to prevent uneven spraying or paint defects. Ensuring the compressor has an appropriate size for your project not only improves efficiency but also minimizes energy consumption and wear on the equipment. Proper airflow management is essential for achieving a smooth finish and avoiding defects. By paying attention to both air quality and noise levels, you’ll guarantee your spray gun performs at its best, delivering smooth, professional results while maintaining a safe and comfortable environment. Proper compressor size selection based on your project needs ensures optimal performance and efficiency. Incorporating tuning techniques can also optimize your equipment’s performance, ensuring you get the best results from your setup.

A well-maintained compressor with adequate filtration can significantly extend the lifespan of your tools and improve overall results.

Determining the Necessary CFM for Smooth Operation

Knowing your spray gun’s airflow requirements is key to selecting the right compressor. To guarantee smooth operation, you need to determine the correct CFM (cubic feet per minute) rating. Check your spray gun’s specifications for the recommended CFM, and compare it to the compressor’s output. Keep in mind that air hose compatibility can affect airflow; a longer or narrower hose may reduce CFM, causing inconsistent spray patterns. Choosing a compressor with a slightly higher CFM than your spray gun’s requirement provides a buffer for fluctuating demands. Also, proper spray gun maintenance, like cleaning filters and fittings, helps maintain ideal airflow and prevents pressure drops. Proper air quality and moisture control are important for optimal spray results and preventing equipment issues. Additionally, understanding air filtration can help ensure that contaminants do not affect the spray finish or damage the equipment. Regularly monitoring air pressure helps maintain consistent spray quality and prevents fluctuations during operation. Being aware of Nissan tuning upgrades can also inform you about potential modifications that might improve equipment performance in specialized applications. Incorporating airline size considerations helps optimize airflow and overall spray performance. By accurately evaluating CFM needs, you’ll achieve smoother finishes and extend your spray gun’s lifespan.

Choosing the Right Tank Size and Pressure Ratings

Selecting the appropriate tank size and pressure ratings guarantees your air compressor provides consistent power for painting projects. A larger tank stores more compressed air, reducing the frequency of compressor cycles and ensuring steady spray patterns. For spray painting, a tank capacity of at least 20 gallons is recommended, but larger tanks help with longer projects. When choosing pressure ratings, look for a unit that can reach 90-125 PSI, which is ideal for most spray guns. Keep in mind that higher pressure ratings may increase noise levels, so noise level considerations are important if you work in noise-sensitive environments. Proper air compressor maintenance, like draining moisture and checking hoses, also ensures your equipment runs efficiently, prolongs its lifespan, and maintains consistent performance. Additionally, understanding Relationships – Personality Test concepts can improve communication with colleagues or clients about project needs and expectations. A well-matched compressor setup can also reduce air pressure fluctuation, leading to better finish quality and more efficient use of materials. Selecting the right airflow capacity is essential to meet the demands of your specific spray gun and project size. Regularly reviewing your compressor’s performance metrics can help identify potential issues before they affect your work quality. Moreover, considering adaptive learning technologies can enhance your understanding of equipment operation and maintenance practices.

Considering Continuous Use and Portability Needs

When considering your air compressor for painting, it’s essential to think about how you’ll use it—whether you’ll need continuous operation or require portability. If you plan to paint thick layers or multiple coats, a compressor with higher CFM and durability is vital for consistent airflow. Conversely, if you need to move around your workspace or job site, portability becomes a priority. Additionally, understanding the importance of professional voiceover techniques can help you communicate your needs effectively to suppliers or when seeking expert advice. To make the right choice:

- Determine if you need a compressor with a larger tank for continuous use without frequent shut-offs.

- Consider noise levels, especially if working in noise-sensitive environments.

- Balance paint thickness requirements with the compressor’s power and size, ensuring it can handle your projects without excess noise or inconvenience.

- Recognizing website performance metrics can also assist in selecting equipment that maintains consistent operation under varying conditions.

- Evaluating the compressor’s ability to handle Glycolic Acid applications can ensure compatibility with specific project requirements.

- Also, consider the duty cycle of the compressor to ensure it can operate continuously during longer painting sessions without overheating or shutdowns.

Tips for Matching Air Compressor Specs With Your Painting Projects

Matching your air compressor specs to your painting projects guarantees smooth operation and quality results. To do this, consider your paint flow needs and nozzle size. A higher paint flow requires a compressor with greater CFM (cubic feet per minute) to maintain consistent pressure, ensuring even coats and minimal overspray. If your nozzle size is larger, it demands more airflow, so choose a compressor that can deliver the necessary volume without dropping pressure. Conversely, smaller nozzles use less air, allowing for smaller compressors. Always check your spray gun’s recommended PSI and CFM ratings, then select an air compressor that meets or exceeds those specifications. Proper matching prevents sputtering, uneven finishes, and wasted paint, giving you a professional-quality result every time. Additionally, understanding air compressor specifications principles can help create a comfortable environment for your workspace. When tuning your compressor, considering performance upgrades can further optimize your painting setup for better efficiency and results. Being aware of airflow requirements ensures you select the right equipment for your specific application, and paying attention to tank size can help maintain consistent air pressure during lengthy projects.

Frequently Asked Questions

Can I Use a Small Portable Air Compressor for Large Painting Jobs?

Using a small portable compressor for large painting jobs isn’t ideal. Portable compressors often lack the air pressure and volume needed for consistent spray patterns on big surfaces. They may run out of air quickly, causing uneven finishes. For large projects, you need a compressor with higher CFM and PSI ratings to maintain steady airflow. Otherwise, you risk poor results and frustration. Always choose a compressor suited for the job size and required air pressure.

How Does Humidity Affect Air Compressor Performance for Spray Painting?

Humidity impact can considerably affect your air compressor’s performance during spray painting. High humidity introduces moisture into the compressed air, reducing compressor efficiency and causing uneven paint application or defects. To maintain ideal results, you should use moisture filters and desiccant dryers, especially in damp conditions. Regular maintenance and monitoring humidity levels help guarantee your compressor operates smoothly, delivering dry, consistent air for a flawless spray finish.

What Maintenance Is Required for Optimal Compressor Operation With Spray Guns?

Think of your compressor as the heart of your spray painting journey. To keep it beating strong, you need regular air filter maintenance to prevent dust from clogging the flow. Also, check the oil level often—like fueling a vehicle—to confirm smooth operation. With these simple steps, you’ll enjoy flawless finishes, trusting your compressor to perform at its best, turning your creative visions into reality.

Is a Higher PSI Always Better for Spray Painting?

When considering if higher air pressure is better for spray painting, remember that more isn’t always better. You need the right balance of air pressure and compressor capacity to achieve a smooth finish. Too much pressure can cause overspray and paint waste, while too little might lead to uneven coverage. Focus on matching your spray gun’s recommended air pressure and guarantee your compressor can handle the required airflow for ideal results.

How Do I Determine the Right Compressor Size for HVLP Spray Guns?

Imagine your project unfolding smoothly, colors blending flawlessly. To achieve this, you need the right compressor size for your HVLP spray gun. Focus on airflow requirements, typically measured in CFM, and match it with a compressor’s capacity. A compressor with sufficient airflow ensures steady spray, preventing sputters or uneven coats. Check your spray gun’s specifications, and choose a compressor that can provide consistent, ample airflow for flawless finishes.

Conclusion

Choosing the right air compressor isn’t just about numbers; it’s about understanding how your tools and projects align. Think of it like a well-balanced team—each part working together seamlessly. When you match your compressor’s specs to your spray gun’s needs, you’ll see smoother finishes and fewer interruptions. It’s a reminder that, sometimes, trusting the basics and doing a little research can turn a good project into a great one.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.