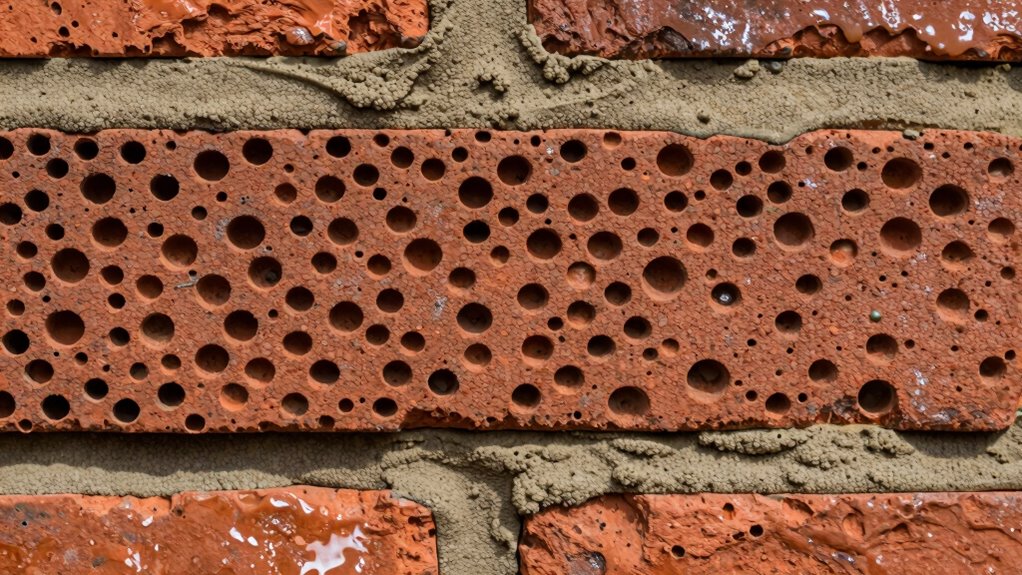

When spraying brick and masonry, it’s easy to focus on quick coverage and protection but forget about porosity, which can trap moisture inside the material. This hidden issue can lead to long-term damage like mold, efflorescence, or weakening of the structure. If moisture gets trapped beneath coatings, it can cause serious problems down the line. To avoid this pitfall, understanding porosity and proper sealing methods are essential — and you’ll discover more if you keep exploring.

Key Takeaways

- Masonry’s natural porosity allows moisture ingress, which can be trapped by improper spraying, leading to long-term deterioration.

- Selecting breathable, moisture-aware coatings is essential to prevent moisture buildup and associated damage.

- Proper surface preparation and assessment of porosity help avoid sealing in moisture and salts.

- Ignoring porosity issues during spraying can result in efflorescence, mold growth, and structural weakening.

- Understanding moisture dynamics ensures effective sealing without trapping water, safeguarding masonry integrity.

Brick and masonry spraying is a popular method for applying protective coatings or finishes quickly and efficiently. It’s a favored choice among contractors because it covers large surfaces in a short amount of time, providing a uniform layer that helps shield the structure from environmental damage. However, while spraying offers speed and convenience, it also introduces some overlooked challenges, especially related to the porosity of the material. Masonry’s natural porosity allows it to absorb moisture, which can lead to long-term issues if not properly managed. When moisture seeps into these surfaces, it can cause deterioration, mold growth, and even structural weakening over time.

One major concern with spraying is guaranteeing that the coating penetrates enough to offer effective moisture barriers without sealing the surface so tightly that moisture gets trapped inside. This is where understanding the porosity trap becomes vital. If you don’t address the material’s porosity, you risk creating a situation where moisture absorption continues underneath the coating, leading to hidden problems that are difficult to detect until they cause damage. Proper sealing and the right choice of protective layer can mitigate this, but it requires knowledge of how much moisture the substrate can absorb and how to prevent it from doing so. Recognizing the material’s moisture dynamics is essential for effective treatment.

Understanding porosity is essential to prevent moisture trapping and hidden damage during masonry spraying.

Efflorescence prevention is another key aspect that often gets overlooked during spraying. Efflorescence appears as white, powdery deposits on the surface caused by soluble salts migrating through the masonry, often brought to the surface by moisture. When moisture absorption isn’t controlled, these salts can travel to the surface and crystallize, ruining the aesthetic appeal and possibly damaging the material itself. To prevent this, you need to guarantee your coating not only protects against water ingress but also effectively reduces the porosity of the masonry. Applying the right sealant or coating can act as a barrier, decreasing moisture penetration and therefore limiting the movement of salts.

It’s important to recognize that spraying isn’t a one-size-fits-all solution. Over-application or improper technique can inadvertently trap moisture, exacerbating issues like efflorescence and structural deterioration. You should assess the specific porosity of each surface and select coatings designed to address these challenges. Proper surface preparation, choosing breathable coatings, and understanding the material’s moisture dynamics will help you avoid the porosity trap. In doing so, you’ll guarantee your masonry remains durable, visually appealing, and protected against moisture-related problems in the long run.

Frequently Asked Questions

How Long Does Brick and Masonry Spraying Last Before Needing Reapplication?

You can expect brick and masonry spraying to last around 5 to 10 years before needing reapplication. To maintain its effectiveness, follow a regular maintenance schedule and consider weather conditions, as extreme weather can accelerate wear. If you notice increased porosity or water absorption, it’s time to reapply. Proper planning guarantees your masonry stays protected, extending its lifespan and preserving its appearance.

Are There Environmentally Friendly Options for Brick and Masonry Spraying?

Did you know that over 70% of homeowners seek eco-friendly alternatives for their projects? You can choose sustainable coatings, which are environmentally friendly options for brick and masonry spraying. These alternatives reduce chemical runoff and energy consumption, helping protect the environment. Using eco-friendly options not only benefits the planet but also improves indoor air quality and long-term durability of your masonry, making your project both sustainable and effective.

Can Spraying Damage the Structural Integrity of Historic Bricks?

Spraying can potentially damage historic bricks if you don’t consider material compatibility. You might unintentionally weaken the bricks or affect their preservation quality, risking long-term damage. To protect the integrity of historic preservation, always consult experts and use compatible, gentle materials. Properly applied, spraying can clean or treat bricks without harm, but neglecting these factors increases the risk of compromising the structure’s durability and historical value.

What Are the Safety Precautions During and After Spraying?

You must prioritize safety during and after spraying. Always wear protective gear like masks, goggles, and gloves to shield yourself from harmful dust and chemicals. Make sure proper ventilation measures are in place to prevent inhaling toxic fumes and to disperse airborne particles. Don’t underestimate these precautions—they’re vital for your health and the integrity of the bricks. Taking these steps keeps you safe and preserves the historic structure’s integrity.

How Does Porosity Affect the Long-Term Durability of Sprayed Masonry?

Porosity effects markedly impact the long-term durability of sprayed masonry. If the surface is highly porous, water can penetrate deeply, causing freeze-thaw damage and weakening the material over time. This raises durability concerns because moisture retention accelerates deterioration. To prevent this, you should choose appropriate sealants and ensure proper surface preparation, reducing porosity and extending the lifespan of your masonry.

Conclusion

Next time you spray brick or masonry, remember the hidden trap of porosity. Like tiny doors, those pores invite moisture to sneak in, lurking unseen behind vibrant surfaces. If you ignore this, water can silently seep, causing cracks and damage over time. Think of your walls as silent guardians—protect them by understanding their porous nature. Don’t let moisture creep in unnoticed; instead, seal and safeguard your masonry before it’s too late.