Quick connects and couplers make your paint sprayer setup faster and easier by allowing you to quickly attach and detach hoses, fittings, and tools without leaks or messes. They help you switch between tasks smoothly, save time on setup and cleanup, and reduce downtime caused by leaks or disconnections. Choosing the right types and proper installation are key to maximizing efficiency and safety. Keep going to discover tips that will optimize your spraying workflow.

Key Takeaways

- Quick connects simplify setup and cleanup by allowing easy attachment and detachment of hoses and fittings.

- Selecting the right material (plastic or metal) ensures compatibility with paint type and environmental conditions.

- Proper installation, including cleaning and secure locking, prevents leaks and ensures reliable operation.

- Regular inspection and maintenance of connectors extend their lifespan and prevent workflow disruptions.

- Using compatible, high-quality couplers optimizes efficiency, safety, and speeds up your paint spraying projects.

Understanding the Benefits of Quick Connects and Couplers

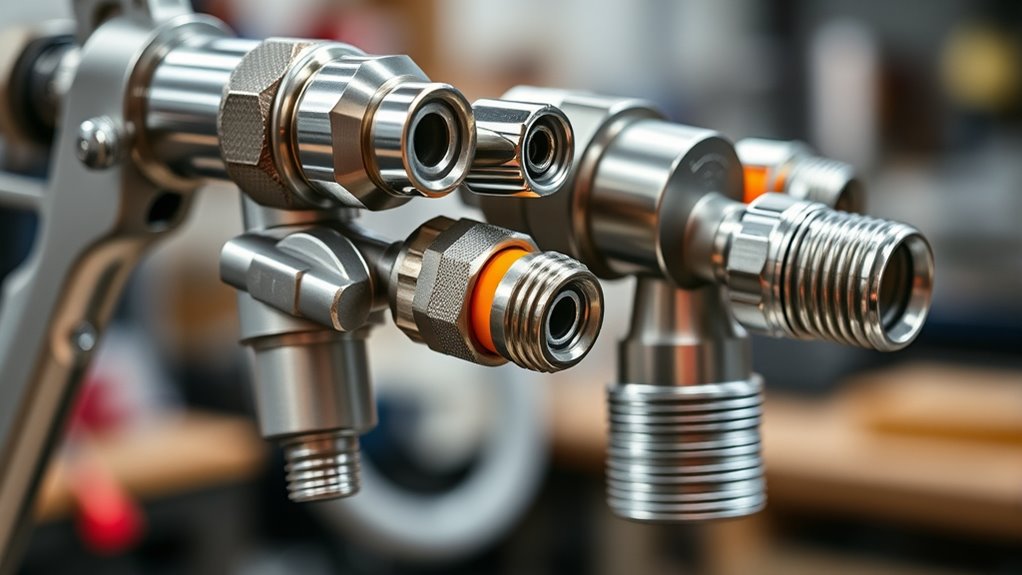

Quick connects and couplers streamline your workflow by making it easy to attach and detach hoses, pipes, or fittings quickly. When you use the right paint sprayer accessories, you benefit from simplified setup and faster clean-up, saving you valuable time. These fittings ensure connection security, preventing leaks and accidental disconnections during operation. They offer a reliable seal, so you can focus on your project without worrying about messes or interruptions. Plus, their quick-release design allows you to switch tools or change hoses effortlessly, enhancing productivity. This convenience makes your painting process smoother and more efficient, especially for larger jobs. Investing in quality quick connects and couplers improves your workflow by providing secure, easy-to-use connections that keep your project moving seamlessly. Additionally, choosing connectors with proper material compatibility ensures durability and long-term performance in various painting environments. Incorporating corrosion resistance features in fittings further extends their lifespan and maintains optimal performance over time. For outdoor or humid conditions, selecting fittings with weatherproofing capabilities can significantly improve longevity and reliability. Ensuring that your fittings are compatible with various brands can also enhance flexibility and ease of use across different equipment. Moreover, selecting airless paint sprayer-specific fittings can optimize the overall efficiency and safety of your spraying setup.

Types of Quick Connects and Couplers for Paint Sprayers

When choosing quick connects and couplers for your paint sprayer, you need to contemplate material compatibility, connection types, and features. Different options are designed to suit various fluids, pressures, and ease-of-use needs. Understanding these differences helps you pick the right fit for your project. For specialized applications, considering tuning options can optimize performance and efficiency. Additionally, selecting components with the appropriate material properties can enhance durability and compatibility with different substances. Ensuring your setup can adapt to automation features may improve overall workflow and reduce manual adjustments, leading to better efficiency and results. Moreover, paying attention to pressure ratings ensures the connections can handle the operational demands safely and reliably. Selecting the right engine tuning methods can also improve the overall performance and longevity of your setup.

Material Compatibility Options

Choosing the right material for your quick connects and couplers is essential to guarantee compatibility with the substances you plan to spray. Different material options affect paint compatibility and durability. For water-based paints, plastics like polypropylene or nylon work well because they resist corrosion and are lightweight. When spraying solvent-based paints or chemicals, metal options such as brass or stainless steel are better, as they withstand harsh chemicals and prevent deterioration. Consider the specific paint or coating you’ll use to ensure the material won’t react or degrade over time. Understanding the material compatibility of your components can help you avoid costly repairs and downtime. It is also important to consider the chemical resistance of the materials to maintain the longevity of your equipment. Selecting the proper material for your quick connects and couplers ensures a smooth, reliable spraying experience with long-lasting performance, especially when considering the compatibility with chemicals. Additionally, reviewing material properties can guide you in choosing options that align with your project requirements to optimize performance and durability. Incorporating knowledge of somatic therapy techniques can also help in maintaining equipment handling comfort and reducing physical strain during frequent use.

Connection Types and Features

Understanding the different connection types and features available for paint sprayers is essential for optimizing your workflow. Quick connect couplers and hose fittings vary in design, making it important to choose the right for your setup. Key features include compatibility with various thread types, ensuring a secure fit, and ease of attachment or removal. Selecting the proper connection types guarantees a reliable setup, reduces downtime, and simplifies maintenance, making your painting process more efficient. Additionally, choosing essential oil compatibility ensures that your connections remain durable and resistant to chemical exposure over time.

How to Choose the Right Connectors for Your Equipment

Are you selecting the right connectors for your equipment? Choosing the correct paint sprayer accessories involves considering both compatibility and durability. Focus on connector materials like brass, stainless steel, or plastic—each offers different strength and chemical resistance. To help, review this comparison:

| Material | Durability | Compatibility |

|---|---|---|

| Brass | High | Widely compatible |

| Stainless Steel | Excellent | Heavy-duty use |

| Plastic | Moderate | Light-duty tasks |

| Aluminum | Good | Corrosion-resistant |

| Rubber | Flexible | Special fittings |

Pick connectors based on your sprayer’s pressure, the type of paint, and environmental conditions. Proper selection guarantees longevity and seamless operation. Considering self-awareness of your equipment needs can further improve your choice, especially regarding pressure compatibility and material resistance. Additionally, understanding how chemical resistance impacts connector longevity can help prevent premature failure. Being aware of corrosion resistance is crucial when working in moist or harsh environments to extend the lifespan of your connectors. Furthermore, assessing ease of installation can streamline setup and maintenance, saving you time and effort.

Step-by-Step Guide to Installing Quick Connects and Couplers

Installing quick connects and couplers is a straightforward process that guarantees a secure and efficient connection between your equipment and hoses. Whether you’re setting up for garden irrigation or automotive repair, proper installation ensures smooth operation. First, choose compatible connectors suited for your needs. Then, follow these steps:

- Clean the fittings to remove debris for a tight seal.

- Insert the male end into the female connector firmly.

- Twist or lock the coupler until it clicks into place.

- Check for compatibility with your specific paint sprayer or system to prevent leaks and ensure optimal performance. Proper installation also helps avoid issues caused by power requirements or electrical compatibility, especially when working with different appliance standards. Ensuring the use of proper fittings is essential for maintaining system integrity and safety. Additionally, verifying system compatibility can prevent potential malfunctions during operation.

Make sure all connections are snug to prevent leaks, especially in garden irrigation systems or automotive repair setups. Test your connection by running water or air through the system to confirm no leaks or disconnections occur. Proper installation simplifies maintenance and enhances performance in any application.

Tips for Maintaining and Replacing Connectors

Regularly inspect your connectors for signs of wear or damage to prevent failures. Always use proper replacement parts to guarantee a secure and reliable connection. Keeping up with these tips helps maintain your system’s performance and safety. Additionally, understanding AI-driven solutions can enhance your approach to troubleshooting and optimizing your setup. For optimal results, ensure that your connectors and couplers are compatible with your paint sprayer model and specifications.

Inspect for Wear and Damage

How can you guarantee your quick connects and couplers stay reliable? Regularly inspect your paint sprayer accessories for wear and damage. Look for cracks, corrosion, or any deformation that could compromise the connection. Damaged connectors can hinder spray pattern adjustment and cause leaks. Keep these tips in mind:

- Check for loose or worn-out seals that may reduce pressure

- Examine the integrity of the coupler’s locking mechanism

- Replace any parts showing signs of corrosion or cracks promptly

Maintaining your connectors ensures smooth operation and a consistent spray pattern. Failing to inspect regularly could lead to uneven coverage or equipment failure. By staying vigilant, you prolong the life of your paint sprayer accessories and keep your setup functioning efficiently.

Use Proper Replacement Parts

When replacing worn or damaged connectors, choosing the right parts is key to maintaining reliable performance. Proper replacement parts guarantee your paint sprayer operates smoothly and safely. Always match connectors to your specific spray system to prevent leaks and pressure issues. During paint sprayer maintenance, use high-quality, compatible connectors to avoid malfunctions. Follow safety precautions by turning off the sprayer and depressurizing the system before replacing parts. Inspect the new connectors for any defects before installation. Using incorrect or substandard parts can lead to leaks, damage, or safety hazards. Regular maintenance with proper connectors keeps your equipment functioning efficiently and extends its lifespan. Prioritize safety and precision to achieve the best results and avoid unnecessary downtime.

Common Mistakes to Avoid When Using Quick Connects

Using quick connects and couplers improperly can lead to leaks, damage, or system failure. To avoid these issues, pay attention to connector material selection, ensuring compatibility with your paint sprayer and the substances you’ll spray. Improper installation can cause unnecessary wear or disconnection during use. Common mistakes include:

- Not cleaning connectors regularly, leading to clogs and leaks

- Forcing incompatible connectors together, damaging the fittings

- Overlooking paint sprayer maintenance, which can cause buildup and reduce connector lifespan

Enhancing Workflow Efficiency With Proper Setup Techniques

Proper setup of your quick connects and couplers is essential for maximizing workflow efficiency. Start by selecting the right paint sprayer accessories that suit your project, ensuring compatibility with your sprayer model. Use connector materials that are durable and resistant to paint chemicals to prevent leaks and disconnections during operation. Keep hoses and fittings clean and free of debris to facilitate smooth connections. Arrange your setup so that connections are quick and easy to access, reducing downtime. Always tighten couplers securely to prevent leaks that can slow your workflow. By paying attention to proper connection techniques and choosing quality connector materials, you minimize interruptions and maintain a steady spray, ultimately speeding up your project and ensuring a professional finish.

Compatibility Considerations for Different Paint Sprayer Models

Choosing the right quick connects and couplers depends heavily on your paint sprayer model, as compatibility varies between brands and systems. To guarantee a proper fit, check your sprayer’s specifications and match connectors accordingly. Using incompatible parts can lead to leaks or inefficient paint flow, risking damage to your equipment. Keep these key points in mind:

Ensure compatibility by checking your paint sprayer’s specs before selecting quick connects and couplers.

- Verify connector sizes and threading standards before purchase

- Consult your paint sprayer’s manufacturer guidelines

- Prioritize high-quality, compatible parts for safe operation

Proper compatibility supports effective paint sprayer maintenance and minimizes safety risks. Always follow safety precautions when connecting or disconnecting components to prevent accidents. Ensuring compatibility not only streamlines your setup but also prolongs your equipment’s lifespan and maintains optimal performance.

Troubleshooting Connection Issues and Leaks

When connection issues or leaks occur with your quick connects and couplers, it’s often due to improper fitting, dirt, or damage. Connection corrosion can cause fittings to seize or leak, especially if moisture gets trapped. Inspect for corrosion and clean or replace affected parts. Incompatible fittings are another common culprit; using mismatched sizes or types can prevent a secure seal, leading to leaks or disconnections. Always verify that your fittings match the manufacturer’s specifications. Dirt or debris trapped inside connectors can also cause leaks or hinder proper connection. Before attaching, clean all components thoroughly. If leaks persist despite proper fitting and cleaning, replace damaged or corroded parts. Regular maintenance and checking for corrosion or incompatible fittings will keep your system running smoothly.

Frequently Asked Questions

Can Quick Connects Be Used With All Types of Paint Sprayers?

You wonder if quick connects work with all paint sprayer types. The truth is, quick connect compatibility hinges on your sprayer’s design and fittings. Some paint sprayer types, like HVLP or airless models, often support quick connects, but not all do. Always check your sprayer’s specifications and fittings to guarantee a proper fit. This way, you can easily switch hoses or accessories without hassle.

Are Quick Connects Compatible With Different Brands of Couplers?

You wonder if quick connects work across different brands of couplers. While quick connects offer convenience, brand compatibility can vary, so you need to check installation tips carefully. To guarantee seamless operation, verify the sizes and threading of your couplers and quick connects, and consider using adapters if needed. By focusing on these details, you’ll achieve a reliable, efficient setup that works smoothly regardless of brand differences.

How Do Quick Connects Affect Paint Flow and Pressure?

Quick connects can impact your paint flow and pressure regulation. They usually allow smoother attachment and detachment, which helps maintain consistent pressure and prevents leaks. However, if they’re not properly fitted or are of low quality, they might cause slight drops in paint flow or pressure fluctuations. To keep peak performance, verify your quick connects are compatible with your equipment and check for secure, tight connections regularly.

Can Quick Connects Be Used for Other Fluid Systems Besides Paint?

Did you know quick connects are used in over 60% of fluid systems? You can definitely use quick connects for different fluid applications beyond paint, as many are designed for universal connection compatibility. This means you can easily transfer liquids like oils, adhesives, or chemicals without hassle. Just make certain you select the right material and size for your specific fluid to avoid leaks or damage, making your work more efficient.

What Safety Precautions Should I Follow When Installing Quick Connects?

When installing quick connects, you should prioritize installation safety by carefully following the manufacturer’s instructions to avoid accidents. Make certain all connections are secure to prevent leaks, which is essential for leak prevention. Wear appropriate protective gear, work in a well-ventilated area, and double-check that fittings are properly aligned before tightening. Taking these precautions helps keep your setup safe, efficient, and free from potential fluid leaks.

Conclusion

By choosing the right quick connects and couplers, you’ll discover how seamless your paint job can become. When your setup flows effortlessly, painting feels less like a chore and more like an art. It’s amazing how a small upgrade can transform your entire project, saving time and frustration. So, take the step today—your smoother, more efficient painting experience might just be a quick connect away, turning every stroke into a satisfying masterpiece.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.