Are you frustrated by blockages causing issues with your airless paint sprayer? Envision it as a smooth, well-functioning tool. The secret to keeping it working perfectly is by regularly cleaning and maintaining it properly.

In this article, we will guide you through the essential steps for cleaning and maintaining your airless paint sprayer. From cleaning after each use to lubricating moving parts, we’ll show you how to extend the lifespan of your sprayer and prevent costly repairs.

So, let’s dive in and discover the secrets to optimal performance!

Key Takeaways

- Regular maintenance ensures optimal performance and longevity.

- Proper maintenance reduces downtime and costly repairs.

- Cleaning after each use prevents clogs and uneven spray patterns.

- Lubricating moving parts prevents rusting and ensures smooth operation.

The Importance of Regular Cleaning and Maintenance

Regularly cleaning and maintaining your airless paint sprayer is crucial to ensure optimal performance and prevent clogs or uneven spray patterns. Neglecting maintenance can have a significant impact on the functionality and lifespan of your sprayer.

By avoiding common cleaning mistakes, such as not cleaning after each use or not properly storing the sprayer, you can avoid costly repairs and downtime.

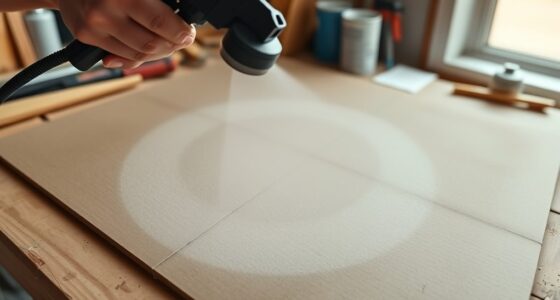

To properly clean your sprayer, start by turning off and disconnecting it from the power source. Flush the fluid section with a suitable cleaning solution or water, and disassemble parts like spray tips and filters for thorough cleaning. Remember to clean the disassembled parts with mild soap or recommended cleaners, and rinse everything thoroughly with clean water.

Essential Steps for Cleaning and Maintenance

To ensure optimal performance and longevity of your airless paint sprayer, make sure you clean and maintain it thoroughly after each use. Cleaning frequency is crucial to prevent clogs and maintain consistent spray patterns.

It is recommended to clean the machine after every use to avoid buildup and ensure efficient operation. Use recommended cleaning solutions or mild soap and water to clean the disassembled parts such as spray tips, filters, and guard assemblies. Rinse all components thoroughly to remove any residue.

Lubricate moving parts to prevent rusting and ensure smooth operation. Proper storage when not in use is also important to protect the sprayer.

Cleaning a Graco Airless Paint Sprayer: Step-by-Step Guide

When cleaning your Graco airless paint sprayer, start by turning off and disconnecting the machine from the power source. Proper cleaning techniques are essential to maintain the functionality and prolong the lifespan of your sprayer.

To clean your Graco airless paint sprayer, flush the fluid section with a suitable cleaning solution or water to remove paint or solvent. Disassemble parts like spray tips, filters, and guard assemblies for thorough cleaning. Use mild soap, water, or recommended cleaners to clean the disassembled parts, and rinse them thoroughly with clean water to remove any residue.

Reassemble the parts according to the manufacturer’s instructions. It is recommended to have water or solvent, clean rags or towels, a brush, and protective gear on hand.

Following these steps will ensure your Graco airless paint sprayer stays in optimal condition.

Enhancing Functionality With Airless Paint Sprayer Accessories

You can enhance the functionality of your airless paint sprayer by using accessories such as extension poles, hose reels, pump protector fluid, and tip cleaner kits.

Extension poles offer the benefit of easily reaching high ceilings or walls, allowing you to tackle painting projects with ease.

Hose reels are essential for maximizing efficiency, providing convenient storage options for long lengths of hose, reducing tangles and tripping hazards.

Pump protector fluid is crucial for lubricating and protecting the internal components of your sprayer during storage, ensuring its longevity.

Tip cleaner kits are a valuable tool for removing dried paint or debris from spray gun tips without causing damage, maintaining consistent spray patterns.

Longevity and Performance: The Benefits of Proper Maintenance

Regular cleaning and upkeep of your airless paint sprayer ensures its longevity and consistent performance. The benefits of regular maintenance are numerous.

Firstly, it prevents clogs and uneven spray patterns, resulting in high-quality results every time. Additionally, it reduces downtime and costly repairs, saving you both time and money. By maintaining your spray gun, you also extend its lifespan, maximizing your investment.

Tips for maintaining spray gun performance include cleaning the machine thoroughly after each use, inspecting and replacing worn parts, lubricating moving parts, and using clean materials. Proper storage when not in use is also crucial.

Remember to clean the filters regularly to prevent debris from entering the system, flush out excess paint to prevent clogs, and clean nozzles and spray tips thoroughly to avoid blockages.

Frequently Asked Questions

What Are Some Common Problems That Can Arise From Neglecting Regular Maintenance of an Airless Paint Sprayer?

Neglecting regular maintenance of your airless paint sprayer can lead to common problems such as clogs, uneven spray patterns, and decreased performance. Without proper cleaning, debris can enter the system and cause blockages, resulting in downtime and costly repairs.

Rusting of moving parts may occur without lubrication, affecting the smooth operation of the sprayer. Regular maintenance is crucial for maintaining the longevity and performance of your airless paint sprayer.

Don’t overlook the importance of regular cleaning for optimal functionality.

Are There Any Specific Cleaning Solutions or Cleaners That Should Be Used for Cleaning an Airless Paint Sprayer?

When it comes to cleaning an airless paint sprayer, there are specific cleaning solutions and alternative cleaners that you can use. It’s important to choose a cleaning solution that is compatible with your sprayer and effectively removes paint or solvent residue.

Some common options include mild soap, water, or recommended cleaners. It’s crucial to follow the manufacturer’s instructions and guidelines for cleaning to ensure the longevity and optimal performance of your airless paint sprayer.

How Often Should Filters Be Cleaned or Replaced in an Airless Paint Sprayer?

To maintain optimal performance, it’s crucial to clean or replace the filters in your airless paint sprayer regularly. The frequency of filter maintenance depends on factors like usage and paint type, but a general guideline is to clean or replace them every 25-50 gallons of paint.

Proper cleaning techniques are essential to ensure effective filtration and prevent debris from entering the system. Following the manufacturer’s instructions and using recommended cleaning solutions will help prolong the lifespan of your sprayer.

Can I Use Any Type of Paint With an Airless Paint Sprayer, or Are There Specific Types That Are Recommended?

You might be wondering if you can use any type of paint with an airless paint sprayer or if there are specific types that are recommended.

Well, here’s an interesting statistic for you: airless paint sprayers are versatile and can handle a wide range of paint types, including latex, oil-based, and even thicker materials like elastomeric coatings.

Unlike HVLP paint sprayers, airless sprayers can handle thicker paints without the need for thinning.

Are There Any Safety Precautions or Guidelines That Should Be Followed When Cleaning or Maintaining an Airless Paint Sprayer?

When it comes to cleaning and maintaining an airless paint sprayer, there are important safety precautions and guidelines to follow.

Always remember to turn off and disconnect the sprayer from the power source before cleaning.

Use suitable cleaning solutions or water to flush the fluid section and remove any paint or solvent.

Take apart parts like spray tips, filters, and guard assemblies for thorough cleaning.

Clean all components with mild soap, water, or recommended cleaners.

Rinse everything thoroughly and reassemble according to the manufacturer’s instructions.

Conclusion

In conclusion, taking proper care of your airless paint sprayer is essential for optimal performance and longevity. By regularly cleaning and maintaining your sprayer, you can prevent clogs, uneven spray patterns, and costly repairs.

Remember to clean the sprayer after each use, inspect and replace worn parts, lubricate moving parts, and store it properly. Don’t forget to clean filters regularly and flush out excess paint to prevent debris and clogs.

Enhance functionality with accessories like extension poles and tip cleaner kits. Following these steps will ensure your sprayer works like a well-oiled machine, making your painting projects a breeze.

So, take care of your sprayer, and it will take care of you!

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.