Fan and cone spray patterns differ mainly in shape and coverage. Fan patterns spray in a flat, elongated, rectangular shape, giving you precise control for flat surfaces and detailed work. Cone patterns are circular and disperses spray evenly in all directions, ideal for irregular shapes or larger areas. Understanding these differences helps you choose the right pattern for your project, so if you’re enthusiastic to learn more about their specific uses and advantages, keep exploring.

Key Takeaways

- Fan patterns produce a flat, elongated spray ideal for precise, flat surface coverage, while cone patterns disperse spray in a circular, conical shape suitable for irregular surfaces.

- Fan patterns typically have narrower spray angles for targeted application; cone patterns often feature wider angles for broader, even coverage.

- Fan patterns offer precise control but can risk overspray; cone patterns maximize efficiency with uniform coverage and less waste.

- Fan patterns are best for detailed work on flat surfaces; cone patterns excel on complex geometries and uneven areas.

- Pattern shape and spray angle directly influence coverage area, application speed, and overall coating quality.

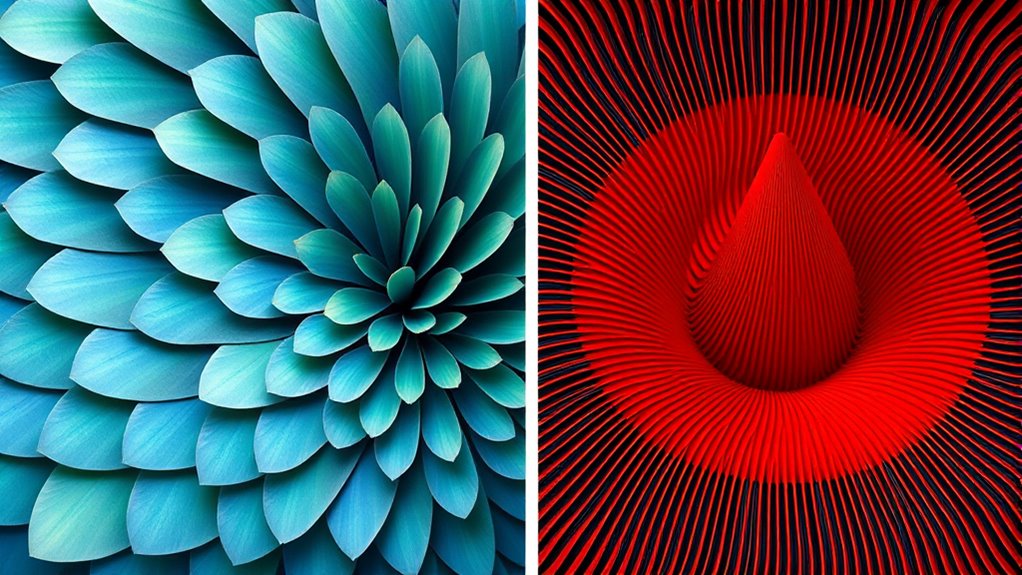

Understanding the difference between fan and cone patterns is essential for anyone involved in spray application or industrial coating processes. When selecting the right pattern, you need to consider how the spray angle influences the coverage and efficiency of your application. A fan pattern produces a flat, elongated spray that spreads out in a broad, rectangular shape. The spray angle here is typically narrow to wide, depending on the nozzle, and it creates a defined, linear pattern. This design allows you to target specific areas with precision, making it ideal for applications that require detailed coverage or when working on flat surfaces. The spray angle in a fan pattern is crucial because it determines how much surface area gets coated with each pass. A wider spray angle covers more area quickly, improving application efficiency, but it also demands careful control to avoid overspray or uneven coating.

In contrast, a cone pattern emits spray in a circular, conical shape, dispersing the coating material in all directions from a central point. The spray angle in a cone pattern is generally larger, covering a broader, more uniform area. This makes cone patterns especially useful when you need to coat irregular surfaces or when a consistent, even layer is essential across complex geometries. Because the spray is dispersed evenly in all directions, cone patterns tend to maximize application efficiency by reducing the number of passes needed to cover a surface. They also help minimize overspray, as the spray is more controlled and predictable within the cone’s boundary. Additionally, proper filtration plays a vital role in maintaining consistent spray patterns and protecting your equipment from clogs.

Your choice between fan and cone patterns hinges on the specific requirements of your project. If you need precise, targeted application on flat surfaces, a fan pattern with a narrower spray angle offers better control. Conversely, if you’re working on complex shapes or require an even coat over a larger or uneven area, a cone pattern with a wider spray angle can boost your application efficiency. Understanding how the spray angle influences coverage helps you optimize your spray technique, reduce waste, and achieve a high-quality finish. Ultimately, knowing the strengths of each pattern enables you to select the right tool for each task, ensuring your coating process is both effective and efficient.

Frequently Asked Questions

Which Pattern Is Better for Small Spaces?

For small spaces, a fan pattern is better because it offers more focused air circulation and airflow distribution. You’ll notice that a fan pattern directs air precisely where you need it, helping to cool down the area quickly. Cone patterns disperse air over a wider area, which isn’t ideal in tight spaces. Choose a fan pattern to maximize efficiency and comfort without overwhelming your small room.

Can Fan and Cone Patterns Be Combined?

Yes, you can combine fan and cone patterns to customize airflow direction effectively. By doing so, you enhance pattern customization, allowing you to direct air where it’s needed most. This combination provides more control over airflow, maximizing comfort and efficiency. You’ll find that mixing the patterns lets you tailor ventilation to your space’s unique layout, creating a balanced and comfortable environment without sacrificing coverage or airflow.

How Do I Choose the Right Pattern for My HVAC System?

To select the right pattern for your HVAC system, consider airflow dynamics and pattern customization. If you need even air distribution across a large space, a fan pattern works best because it provides broad airflow coverage. For targeted airflow or specific zone cooling, a cone pattern offers focused delivery. Assess your room layout and comfort needs, then select the pattern that guarantees ideal airflow and efficiency for your space.

Are There Specific Industries That Prefer One Pattern Over the Other?

You’ll find that certain industries prefer specific ventilation types to optimize airflow distribution. For example, manufacturing plants often favor fan patterns for broad coverage, while cleanroom environments lean towards cone patterns for precise airflow control. These preferences depend on airflow distribution needs, ensuring effective ventilation. Your choice hinges on understanding how each pattern suits your industry’s ventilation requirements, helping you achieve efficient and safe airflow management.

Do Different Patterns Affect Energy Efficiency?

Different patterns do impact energy efficiency by influencing airflow optimization. Fan patterns typically provide broader airflow, which can improve cooling or ventilation with less energy use. Cone patterns concentrate airflow, which might require more energy but can target specific areas effectively. Choosing the right pattern depends on your needs; optimizing airflow guarantees energy savings and better performance. So, selecting the appropriate pattern helps maximize efficiency and reduces unnecessary energy consumption.

Conclusion

So, now you see how fan and cone patterns differ, each serving different purposes. You might think, “But aren’t they pretty similar?” Actually, choosing the right pattern depends on your specific needs, like coverage area or material flow. Don’t worry if it feels confusing at first—you’ll get the hang of it with a little practice. Once you understand their strengths, selecting the right pattern becomes easier, making your work more efficient and effective.

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.