Airless and HVLP sprayers differ mainly in pressure, spray control, and ideal uses. An airless sprayer delivers high pressure, handling thick paints for large areas quickly, making it great for exteriors and walls. HVLP sprayers operate at lower pressure, providing more control and precision, perfect for detailed finishes and furniture. Choosing the right one depends on your project size and detail needs—stick around, and you’ll learn everything to make an informed decision.

Key Takeaways

- Airless sprayers handle thick paints and large surfaces, while HVLP sprayers are suited for detailed, delicate finishes.

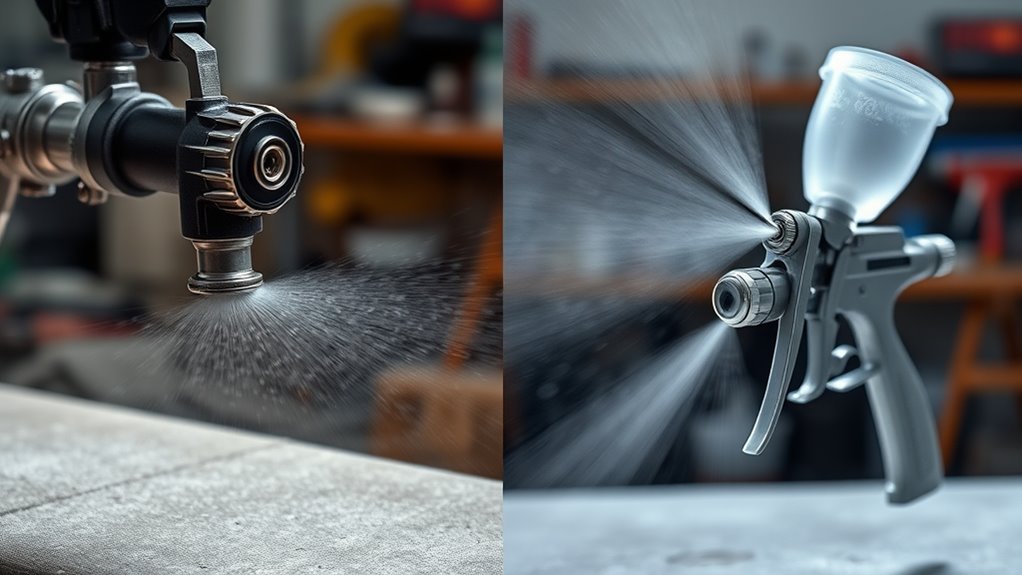

- Airless systems use high pressure for fast coverage; HVLP offers softer, more controlled spray with less overspray.

- Airless sprayers require thorough cleaning and nozzle maintenance; HVLP systems are easier to clean and maintain.

- Airless tools are ideal for exterior walls and fences; HVLP excels in fine finishes and interior work.

- Proper system choice depends on project size, paint type, and desired finish quality.

When choosing the right paint spray system, understanding the differences between airless and HVLP (High Volume Low Pressure) sprayers is vital. One of the key factors to contemplate is the types of paint each system handles best. Airless sprayers are versatile and can handle thick, heavy paints like latex, enamels, and primers without needing thinning. They deliver a high-pressure stream that atomizes paint into a fine spray, making them ideal for large surfaces such as walls, fences, or exteriors. HVLP sprayers, on the other hand, work better with thinner paints, stains, and lacquers. Because they operate at lower pressure, HVLP systems produce a softer, more controlled spray, which is perfect for detailed work or finishes that require precision and minimal overspray.

Knowing the types of paint each system can handle influences your choice and impacts your spray gun maintenance routine. Airless sprayers, with their high-pressure output, require regular cleaning to prevent clogging, especially when switching between different paint types. You’ll want to thoroughly flush the system after each use, paying close attention to the nozzle and filters. HVLP sprayers, which operate at lower pressure, tend to be easier to maintain. However, since they often spray thinner paints, it’s still vital to clean the spray gun thoroughly after each use to prevent buildup that can clog the nozzle or affect spray quality. Proper maintenance ensures consistent performance and extends the lifespan of your spray gun, no matter which type you choose.

Choosing the right paint and maintaining your sprayer ensures optimal performance and longevity.

Additionally, spray gun maintenance involves checking for wear and tear on parts like nozzles, seals, and filters. For airless systems, replacing worn nozzles and cleaning filters regularly keeps the system operating smoothly and maintains a fine, even spray. HVLP systems benefit from gentle cleaning, avoiding damage to delicate components. Both systems require you to inspect hoses and connections for leaks or damage before each use to prevent issues during spraying.

Furthermore, understanding the technology differences between these systems can help you optimize your workflow and achieve better results. Ultimately, your choice depends on the project scope and the types of paint you’re using. If you’re tackling large, rough surfaces with thick paints, an airless sprayer’s power and volume make it a good fit. For projects demanding precision and a delicate finish, an HVLP system’s controlled spray is better. Proper spray gun maintenance tailored to each system’s needs ensures you get the best results and longevity from your equipment. Understanding these distinctions helps you pick the right tool and keep it performing at its best, making your painting projects smoother and more efficient.

Frequently Asked Questions

Can I Use Airless and HVLP Sprayers Interchangeably?

You can’t really use airless and HVLP sprayers interchangeably because of their compatibility and design differences. Airless sprayers are better for large, thick coatings and provide faster coverage, while HVLP sprayers offer more control for detailed work. Their equipment versatility is limited, so choosing the right sprayer depends on your project needs. Using the wrong type can lead to inconsistent results or equipment damage.

Which Sprayer Is Better for Detailed Woodworking Projects?

For detailed woodworking projects, HVLP sprayers are your best choice. Imagine you’re finishing a delicate, intricate cabinet, and the fine spray pattern guarantees a smooth, consistent finish without overspray. HVLPs provide superior control and finish quality, making them ideal for precision work. Their ability to produce a refined spray pattern helps you achieve professional results on even the most detailed pieces, giving your craftsmanship a flawless look.

How Does Paint Viscosity Affect Sprayer Choice?

Paint viscosity considerably impacts your sprayer choice because thicker, high-viscosity paints require a sprayer with higher pressure, like an airless sprayer, to guarantee proper atomization. If your paint is more fluid with low viscosity, an HVLP sprayer works better, providing fine finishes with less overspray. Always consider paint consistency and viscosity impact when selecting your sprayer to achieve smooth, even coats without clogging or uneven application.

Are There Environmental Considerations Between Airless and HVLP?

You might find it surprising, but both airless and HVLP sprayers have environmental impacts. HVLP systems typically produce fewer VOC emissions and are more eco-friendly, making them a better choice if you’re aiming to reduce environmental harm. Airless sprayers, while efficient, can emit more VOCs and overspray. Choosing an eco-friendly option depends on your project needs, but prioritizing HVLP can help you minimize your environmental footprint.

What Safety Precautions Are Necessary for Each Type?

You should wear protective gear like masks, goggles, and gloves to avoid inhaling fumes or getting paint on your skin. Make certain proper ventilation to disperse fumes safely, especially for airless sprayers which generate more overspray. For HVLP, good airflow prevents buildup of vapors. Always follow manufacturer instructions, work in well-ventilated areas, and use respiratory protection if necessary to keep yourself safe during painting.

Conclusion

In the end, choosing between airless and HVLP depends on your project and priorities. You might find yourself reaching for the HVLP for detailed, smooth finishes, while the airless sprayer becomes your go-to for larger, quicker jobs. It’s funny how the right tool can turn a messy project into a satisfying success. Sometimes, it’s just a matter of coincidence—finding the perfect spray method that makes your work easier and more enjoyable.

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.