Before beginning a painting project using a secondhand airless paint sprayer, it is crucial to carefully assess its functionality and overall performance. Examining it with the scrutiny of a detective helps to pinpoint any defects or operational problems, guaranteeing that the sprayer produces an optimal spray pattern, maintains consistent pressure, and functions at its peak efficiency.

By inspecting the sprayer’s exterior and interior, checking the motor and pump, and assessing the pressure and spray pattern, one can make an informed decision based on its condition and capabilities.

So, grab your pressure gauge and safety goggles, and let’s dive into the world of testing a used airless paint sprayer.

Key Takeaways

- Testing and evaluating a used airless paint sprayer ensures optimal performance and functionality.

- Thorough testing helps to identify and troubleshoot common issues such as clogged nozzles, damaged hoses, and malfunctioning motors or pumps.

- Assessing components like the spray gun, nozzles, hose, and connections allows for the identification of any defects or malfunctions.

- Proper cleaning and maintenance practices, including regular flushing, cleaning filters and nozzles, lubricating moving parts, and following manufacturer’s guidelines, are essential to maintain the sprayer’s performance and extend its lifespan.

The Importance of Testing a Used Airless Paint Sprayer

Testing a used airless paint sprayer is important to ensure its performance and functionality, helping to avoid potential issues and save time and money.

When purchasing a used airless paint sprayer, there are common issues to look out for. These include clogged nozzles, damaged hoses and connections, and malfunctioning motors or pumps. By thoroughly testing the sprayer, one can identify these issues and troubleshoot and fix them accordingly.

Tips for troubleshooting and fixing problems with a used airless paint sprayer include inspecting the exterior and interior of the sprayer for damages and signs of wear and tear, checking the motor and pump functionality for any unusual noises or inconsistencies, and testing the pressure and spray pattern.

Necessary Tools and Equipment for Testing

The importance of having proper tools and equipment for evaluating the performance and functionality of a used airless paint sprayer cannot be overstated. To ensure accurate testing and reliable results, it is essential to have the following tools and equipment:

| Tools and Equipment | Purpose | Safety Precautions |

|---|---|---|

| Pressure gauge | Measures the pressure of the spray | Regular maintenance is required |

| Cleaning solution | Cleans the paint sprayer | Wear safety goggles |

| Safety goggles | Protects eyes from splatters | Use in a well-ventilated area |

| Test surface | Provides a surface for testing | Avoid inhaling fumes |

Inspecting the Exterior and Interior of the Paint Sprayer

When inspecting a paint sprayer, one should carefully examine the overall condition and functionality of both the exterior and interior components. This thorough inspection is essential to identify any common issues and implement appropriate troubleshooting techniques.

The exterior should be checked for damages and signs of wear and tear, which can affect the sprayer’s performance. The power switch should be verified for proper functioning, and the filters and valves should be inspected for any clogs or blockages.

Moving to the interior, the motor should be listened to for any unusual noises that could indicate a malfunction. The trigger should be tested for a consistent spray pattern, and the pump functionality should be verified using a pressure gauge.

Checking the Motor and Pump Functionality

By listening for unusual noises and testing the trigger for consistent spray patterns, one can verify the functionality of the motor and pump in a paint sprayer. Checking the motor noise is crucial as any strange sounds may indicate underlying issues. It is important to ensure that the motor runs smoothly, without any grinding or squeaking noises.

Additionally, testing the trigger for consistent spray patterns helps assess the pump pressure. A properly functioning pump should provide a steady and even spray pattern. By measuring the pump pressure with a gauge, one can determine if it falls within the recommended range. Adequate pump pressure is essential for achieving optimal paint application.

Through these tests, one can ensure that the motor and pump are in good working condition, guaranteeing the efficiency and effectiveness of the paint sprayer.

Testing Pressure and Spray Pattern

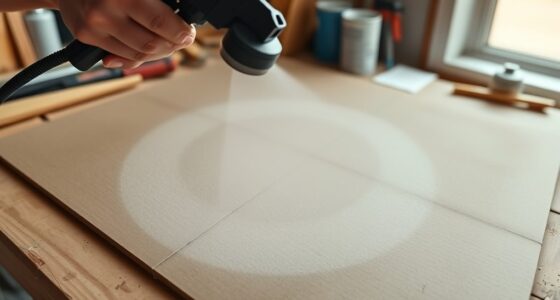

To assess the pressure and spray pattern, one can inspect the nozzle and hose for clogs and adjust the pressure settings for the desired spray distance. Achieving optimal performance requires precise adjustments.

Start by examining the nozzle and hose for any obstructions that may affect the spray pattern. Clear any clogs or debris to ensure a smooth and consistent flow of paint.

Next, adjust the pressure settings according to the desired spray distance. This will determine how far the paint will travel and the coverage it will provide. By fine-tuning the pressure, one can achieve an even and uniform spray pattern, resulting in a professional-looking finish.

It is important to regularly test the pressure and spray pattern to maintain the efficiency and effectiveness of the airless paint sprayer.

Evaluating the Spray Gun and Nozzles

Inspecting the spray gun and nozzles allows for a thorough evaluation of their condition and ensures optimal performance. When evaluating spray gun performance and troubleshooting nozzle issues, it is crucial to pay attention to the following:

-

Spray Pattern: Checking the spray pattern is essential to ensure an even and consistent application of paint. Any inconsistencies may indicate nozzle blockages or defects.

-

Nozzle Condition: Examining the nozzles for wear and tear, cracks, or damages is crucial. Defective nozzles can lead to poor spray patterns, overspray, or uneven coverage.

-

Compatibility: Ensuring the compatibility between the spray gun and nozzles is important for achieving the desired performance. Using the wrong nozzle size or type can result in inefficiency or unsatisfactory results.

Assessing the Hose and Connections

Assessing the hose and connections ensures proper functionality and avoids potential issues with the airless paint sprayer. Evaluating hose durability is crucial in determining if it can withstand the pressure and demands of the paint spraying process. Any signs of wear and tear, such as cracks or leaks, should be carefully inspected.

Troubleshooting connection issues is also important to ensure a secure and tight fit between the hose and the sprayer. Loose or faulty connections can lead to paint leakage or uneven spray patterns. By thoroughly examining the hose and connections, one can identify any potential problems and address them before they cause disruptions or damage during painting projects.

Regular maintenance and proper cleaning practices can also contribute to the overall durability and longevity of the hose and connections.

Proper Cleaning and Maintenance Practices

Regular cleaning and maintenance practices are essential for ensuring the longevity and optimal functioning of the hose and connections in an airless paint sprayer. Neglecting these tasks can lead to clogs, leaks, and decreased performance.

To keep the hose and connections in top condition, here are some cleaning techniques and maintenance tips to follow:

- Regularly flush out the system with a cleaning solution to remove any residue or paint buildup.

- Inspect the hose for any cracks or damage, and replace if necessary.

- Clean the connections and fittings to prevent any blockages or leaks.

Overall Performance and Efficiency Evaluation

After ensuring proper cleaning and maintenance practices for a used airless paint sprayer, the next step is to evaluate its overall performance and efficiency. This evaluation is crucial in identifying any defects or malfunctions that may affect the sprayer’s functionality. By conducting a thorough assessment, one can determine if the sprayer meets the desired standards for performance and functionality.

During the evaluation process, it is important to pay attention to various aspects of the sprayer. This includes assessing the spray gun and nozzles, checking the hose and connections, and verifying the overall performance and efficiency. By inspecting these components, one can determine if the sprayer is capable of delivering a smooth and even finish on painting projects.

Identifying any defects or issues during the evaluation allows for informed decision-making. If significant problems are found, it may be necessary to seek repairs or consider alternative options.

Overall, evaluating the performance and efficiency of a used airless paint sprayer is essential in ensuring its reliability and effectiveness.

Frequently Asked Questions

How Often Should a Used Airless Paint Sprayer Be Tested for Performance and Functionality?

The frequency of testing for used airless paint sprayers and its impact on performance play a crucial role in ensuring their functionality.

Regular maintenance is important for used airless paint sprayers to avoid potential issues and ensure optimal performance.

By testing the sprayer regularly, one can identify any defects or malfunctions, assess the spray pattern and pressure, and make necessary adjustments for a smooth and efficient painting experience.

Overall, regular testing and maintenance are essential for the longevity and reliability of the sprayer.

Can Any Type of Cleaning Solution Be Used During the Testing Process, or Is There a Specific Solution Recommended?

When testing the performance and functionality of a used airless paint sprayer, it’s important to use a suitable cleaning solution.

While any cleaning solution may be effective, it’s recommended to use a specific solution that is compatible with the paint sprayer’s components and materials.

This ensures optimal cleaning and avoids any potential damage.

Additionally, it’s important to follow recommended safety precautions when handling and using the cleaning solution. This includes wearing safety goggles and gloves to protect against any potential chemical hazards.

Are There Any Specific Safety Precautions That Should Be Taken When Testing a Used Airless Paint Sprayer?

Safety measures should be taken when testing a used airless paint sprayer. It’s important to wear safety goggles to protect the eyes from any potential spray or debris.

Additionally, proper ventilation should be ensured to avoid inhaling any fumes.

As for the recommended cleaning solution, it’s advisable to use a solution specifically designed for paint sprayers. This will help in effectively removing any paint residue and ensuring the sprayer is clean and ready for use.

What Are Some Common Signs of Wear and Tear That Should Be Looked for During the Inspection of the Paint Sprayer?

During the inspection of a used airless paint sprayer, it’s important to look for common signs of wear and tear. These may include scratches, dents, and rust on the exterior of the sprayer. It’s also important to check for worn or frayed hoses and loose or damaged connections. Additionally, it’s crucial to check for leaks or drips and inspect the condition of the filters and valves.

A recommended cleaning solution for testing a paint sprayer is a mixture of warm water and mild detergent.

Are There Any Specific Guidelines or Best Practices for Adjusting the Pressure Settings for the Desired Spray Distance?

When adjusting the pressure settings for the desired spray distance, there are some helpful tips to keep in mind.

First, start with a lower pressure setting and gradually increase it until the desired spray distance is achieved.

If the spray is too narrow or concentrated, decrease the pressure; if it’s too wide or scattered, increase the pressure.

It’s important to troubleshoot any common spray distance issues by adjusting the pressure accordingly to ensure optimal performance and an even finish on painting projects.

Conclusion

In conclusion, testing the performance and functionality of a used airless paint sprayer is of utmost importance. It allows for the identification of any defects or malfunctions, ensuring a smooth painting process and avoiding potential issues.

By assessing the spray pattern, pressure, and overall functionality, one can make an informed decision based on the sprayer’s condition and capabilities.

Additionally, proper cleaning and maintenance practices help prolong the sprayer’s lifespan and maintain its efficiency.

By thoroughly evaluating all aspects of the sprayer, one can ensure optimal performance and evoke a sense of confidence in their painting project.

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.