To diagnose whether your airless or HVLP sprayer has flow or atomization problems, check the spray pattern first. If the spray is uneven, it might be a clogged nozzle or worn parts. For flow issues, verify pressure levels and clean filters; for atomization problems, ensure proper gun adjustments and nozzle maintenance. Recognizing these differences helps you troubleshoot effectively—continue exploring for more tips to keep your sprayer performing at its best.

Key Takeaways

- Check spray pattern consistency to identify clogging, wear, or setup issues affecting both flow and atomization.

- Inspect and clean nozzles, filters, and spray tips regularly to prevent flow and atomization problems.

- Verify pressure settings and system components to distinguish between flow restrictions and atomization deficiencies.

- Adjust paint viscosity and pressure levels appropriately to optimize spray quality and prevent oversizing droplets.

- Regular maintenance and equipment checks help diagnose whether issues stem from flow disruptions or poor atomization.

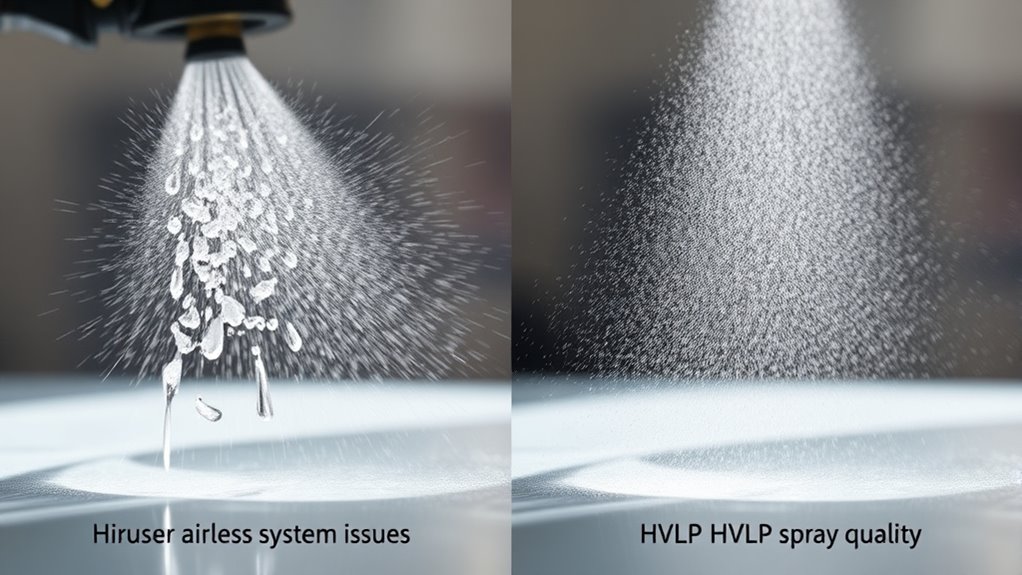

Choosing between airless and HVLP spray systems can considerably impact your project’s efficiency and finish quality. When diagnosing issues related to flow and atomization, understanding how each system operates is essential. One common problem you might encounter is an inconsistent spray pattern, which directly affects the smoothness and evenness of your finish. If your spray pattern is irregular or uneven, it’s likely due to either a clog, worn equipment parts, or improper setup. Regular equipment maintenance becomes vital here—cleaning filters, inspecting nozzles, and ensuring proper pressure levels can help maintain a consistent spray pattern. For airless systems, a clogged or damaged nozzle can cause uneven flow, while in HVLP setups, a worn or improperly adjusted gun affects atomization quality.

Flow issues are often mistaken for atomization problems but are distinct. If you notice a weak or sporadic flow of paint, it might stem from a clogged inlet, low pressure, or a faulty pump in an airless sprayer. HVLP systems, which operate at lower pressure, are particularly sensitive to hose blockages or leaks, which restrict flow. Addressing flow problems usually involves checking and cleaning the intake filters, verifying pressure settings, and ensuring there’s no air trapped in the system. Regular equipment maintenance plays a key role here—keeping components clean and replacing worn parts prevents flow disruptions that compromise your project timeline. Additionally, understanding the influence of paint viscosity on flow and atomization helps optimize your spraying process.

Atomization, on the other hand, refers to how well the paint breaks into tiny droplets to form a fine, even mist. Poor atomization results in a rough, uneven finish, often with visible spray lines or drips. In airless sprayers, inadequate atomization can be caused by excessive pressure, which oversizes the spray droplets, or by a worn nozzle that no longer produces a fine mist. For HVLP systems, improper gun adjustments or dirty nozzles hinder atomization, as the system relies on high volume low pressure to produce a smooth spray. To diagnose atomization issues, you should first check the spray pattern—if it’s inconsistent or overly wide, it indicates a problem with the nozzle or pressure settings. Regularly inspecting and maintaining your equipment ensures that the nozzle or spray tip remains in good condition, promoting ideal atomization.

In both systems, diagnosing flow versus atomization issues requires a keen eye and routine maintenance. Staying on top of equipment checks, cleaning, and adjustments helps prevent common problems from escalating. Recognize the signs—such as uneven spray patterns, inconsistent flow, or rough finishes—and address them promptly. With proper diagnosis and regular upkeep, you’ll achieve a smooth, professional finish, whether working with airless or HVLP systems.

Frequently Asked Questions

How Can I Test if My Spray Gun Is Working Properly?

To test if your spray gun is working properly, start with spray gun calibration by adjusting the fluid and air controls for ideal atomization. Then, perform airflow measurement by spraying onto a flat, clean surface and observing the spray pattern. Consistent, even coverage indicates proper functioning, while uneven or inconsistent spray suggests you need to fine-tune the airflow or check for clogs. Regular testing ensures a smooth, professional finish.

What Are Signs of a Clogged Nozzle in Airless and HVLP Sprayers?

Did you know that clogged nozzles are responsible for 60% of spray gun issues? You’ll notice uneven spray, drips, or inconsistent flow, indicating nozzle blockage. In airless and HVLP sprayers, poor spray consistency and spurts often point to a blocked nozzle. Regularly check for debris or paint buildup, and clean it thoroughly to guarantee smooth atomization and consistent coverage.

Can Improper Setup Cause Flow Issues Without Affecting Atomization?

Yes, improper setup can cause flow issues without affecting atomization. If you don’t regulate pressure correctly or if the fluid viscosity is too high, you might see inconsistent flow while atomization remains unaffected. Make sure your pressure regulation is set according to the paint’s viscosity, and adjust it to maintain steady flow. This will help prevent flow problems without impacting the atomization process.

How Do Environmental Factors Influence Spray Pattern and Flow?

Ever wonder how weather impacts your spray job? Humidity effects can cause paint to dry unevenly or clog your spray tip, while temperature fluctuations can affect viscosity, leading to inconsistent flow and spray pattern. High humidity slows evaporation, causing runs, whereas cold temperatures thicken the paint, reducing flow. By understanding these environmental factors, you can adjust your technique or equipment to maintain ideal spray quality.

Are There Specific Maintenance Tips to Prevent Flow and Atomization Problems?

To prevent flow and atomization problems, you should regularly inspect and maintain your spray equipment. Clean nozzles thoroughly after each use to prevent clogs, which can disrupt spray patterns. Additionally, perform routine inspections to identify wear or damage early. Proper maintenance guarantees consistent flow and atomization, reduces downtime, and extends your equipment’s lifespan. Staying proactive with these practices keeps your spraying process smooth and efficient.

Conclusion

In the end, understanding whether you’re dealing with airless or HVLP issues comes down to knowing their quirks—much like a seasoned captain spotting a storm at sea. You’ll quickly see if the flow’s too weak or the atomization’s off, and can troubleshoot like a pro. Remember, don’t let your paint jobs turn into a “Faux-ntasia.” With a little patience and the right knowledge, you’ll be back to painting like it’s the Renaissance in no time.

Franz came aboard the Paint Sprayer Zone team with a background in both journalism and home renovation. His articulate writing style, combined with a passion for DIY projects, makes him an invaluable asset. Franz has a knack for breaking down technical jargon into easy-to-understand content, ensuring that even the most novice of readers can grasp the complexities of paint sprayers.