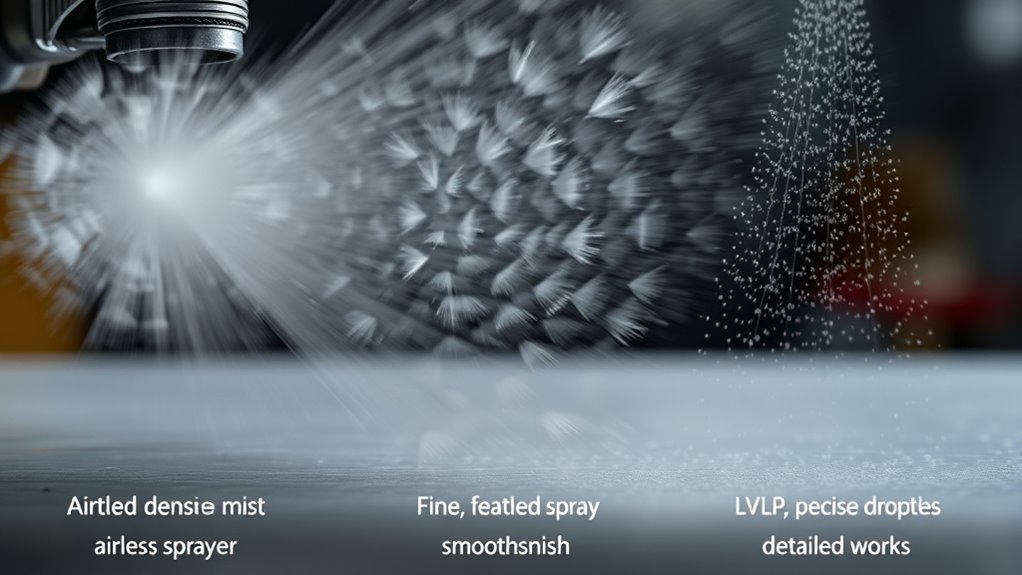

If you want to choose between airless, HVLP, or LVLP sprayers, understand their strengths: airless provides fast coverage for large areas but less finesse, HVLP offers smooth finishes with reduced overspray suitable for furniture and detail work, and LVLP excels at precision for crafts and automotive projects with minimal waste. Knowing these differences helps match your project needs. Explore further to find out which sprayer is best for your specific application.

Key Takeaways

- Airless sprayers are high-pressure, fast, and ideal for large surfaces; HVLP and LVLP focus on precision with lower pressure.

- HVLP offers smooth finishes with minimal overspray, suitable for furniture and detailed work; LVLP excels in fine detail applications.

- Airless sprayers provide high coverage quickly but may lack finesse; HVLP and LVLP prioritize control and quality over speed.

- Maintenance and proper technique are essential across all sprayer types to achieve optimal results and efficiency.

- Choose the sprayer based on project size, desired finish quality, and level of detail for best performance.

How Airless Sprayers Work and Their Key Features

Airless sprayers work by pumping paint at high pressure through a hose and out of a specialized nozzle, creating a fine, even spray without the need for a traditional air compressor. This process allows you to handle thicker paints with ease, as maintaining consistent paint consistency is vital for a smooth finish. The high-pressure system ensures quick coverage of large surfaces, making it ideal for big projects. Additionally, equipment portability is a significant advantage—you can easily move the sprayer around the work area without hassle. Because of their design, airless sprayers are often more compact and lightweight than other types, allowing you to work efficiently in different locations. Their cost-effectiveness and ability to deliver high-quality finishes in less time make them a popular choice for many painting tasks.

The Mechanics and Benefits of HVLP Systems

HVLP systems use low pressure and controlled airflow to deliver paint smoothly, giving you better control over the spray. This setup reduces overspray and waste, making your projects more efficient. Plus, it results in a high-quality surface finish with fewer imperfections. Additionally, HVLP systems are often preferred for their precision and control, which is especially valuable in detailed or delicate applications. The consistent application of paint also minimizes material waste, saving resources and costs. Their ability to produce a professional-quality finish makes them suitable for both DIY enthusiasts and professional painters.

Airflow and Pressure

Have you ever wondered how certain spray systems deliver fine, precise finishes with less overspray? It all comes down to airflow and pressure control. HVLP systems excel because they utilize airflow dynamics optimized through pressure regulation. By maintaining lower pressure at the spray gun, you get a steady, controlled airflow that produces a fine mist, reducing waste and overspray. The pressure regulation ensures consistent atomization, which results in smoother, more even coatings. This precise airflow allows you to work with thinner materials and achieve detailed finishes without sacrificing speed. Understanding how airflow and pressure work together helps you fine-tune your spray setup for better results, making HVLP systems a reliable choice for detailed painting tasks. Additionally, color accuracy plays a crucial role in achieving high-quality finishes. Proper pressure regulation can also contribute to better color consistency by ensuring uniform material delivery, and being aware of AI safety measures can help prevent unintended malfunctions during operation.

Efficiency and Waste Reduction

Because of their design, HVLP spray systems considerably improve efficiency and reduce waste during painting projects. They transfer more paint onto the surface with less overspray, meaning you utilize your paint more effectively. Proper paint mixing guarantees the spray pattern stays consistent, minimizing drips and wasted material. Additionally, HVLP systems require a smaller compressor size compared to other sprayers, making them energy-efficient and easier to operate. This lower compressor demand not only cuts down on energy costs but also reduces noise. By controlling airflow and pressure precisely, HVLP sprayers help you spray smoothly with less paint loss. Overall, they provide a cleaner, more controlled application process, saving you both time and money by reducing waste and maximizing paint coverage. Incorporating vertical storage solutions can further enhance your workspace efficiency when using these sprayers. Furthermore, airflow control plays a crucial role in maintaining consistent spray quality and minimizing material waste. As a result, understanding and utilizing sprayer mechanics can lead to improved results and a more sustainable painting process.

Surface Finish Quality

Ever wondered how to achieve a smooth, professional finish with your paint job? HVLP systems excel in delivering a high-quality surface finish thanks to their ability to produce a consistent spray pattern. This results in fewer overspray and a more even coat. To maximize finish quality, consider these points:

- Adjust the spray pattern for ideal coverage

- Use paint with the right viscosity for smooth atomization

- Maintain consistent spray distance and speed

- Focus on even, overlapping passes

- Regular maintenance and cleaning of the spray gun can also improve atomization and finish quality, especially when managing paint viscosity and spray consistency. Additionally, understanding airless, HVLP, and LVLP sprayer differences can help select the right tool for your specific project needs. Being aware of proper spray technique can further enhance your results and reduce paint waste. Recognizing the benefits of HVLP systems can guide you in choosing the most suitable spraying method for achieving optimal surface finishes. Proper vibrational control during spraying can also contribute to a more uniform application and better overall results.

Understanding LVLP Sprayers and Their Unique Advantages

LVLP sprayers offer a precision finish that’s ideal for detailed work. They reduce overspray and waste, making your projects more efficient. Plus, they excel at handling fine details, giving you a polished, professional look. Incorporating proper techniques and poses can further enhance your results by ensuring consistent application and precision. Additionally, understanding the factors affecting spray quality can help you optimize performance and achieve the best possible finish. Being aware of spray pattern control helps in refining your technique for smoother results and minimized rework.

Precision Finish Capabilities

Are you looking for a spray system that delivers a flawless finish with minimal overspray? LVLP sprayers excel in providing high-quality, detailed results, making them ideal for precision work. Their sprayer ergonomics allow for better control and comfort during prolonged use, reducing fatigue and improving accuracy. Because they operate at lower pressure, they produce a fine, even spray pattern, ensuring smooth, professional finishes. Additionally, LVLP sprayers have a smaller environmental impact due to less overspray and waste. Store hours can also influence the availability of supplies and assistance when preparing for projects. An important benefit is their ability to achieve consistent coating thickness, which is critical for high-quality finishes. Key advantages include:

- Precise control over spray pattern and thickness

- Reduced overspray for cleaner application

- Enhanced sprayer ergonomics for better comfort

- Lower environmental impact through efficient material use

This combination makes LVLP sprayers perfect for detailed projects and finishing touches.

Reduced Overspray and Waste

Since controlling overspray is essential for a clean, efficient finish, understanding how LVLP sprayers minimize waste can considerably improve your spraying results. LVLP sprayers produce a fine, controlled spray pattern that reduces excess paint in the air, leading to less overspray and less wasted material. This precision not only saves you money but also promotes better paint adhesion by applying a consistent coat, ensuring a durable finish. Plus, the reduced overspray diminishes environmental impact by limiting airborne paint particles and VOC emissions. With less waste, you’ll spend less time cleaning up and more time on your project. Additionally, customizable spray settings allow for tailored application, further enhancing efficiency and quality. Overall, LVLP sprayers help you achieve a cleaner, more efficient process while supporting eco-friendly practices.

Suitable for Fine Details

Because of their ability to produce a very fine and controlled spray, LVLP sprayers are especially well-suited for detailed work. Their design allows you to handle intricate patterns with precision, making them ideal for projects requiring finesse. The sprayer ergonomics help reduce fatigue during extended use, giving you better control over the spray pattern. Adjusting for paint viscosity is straightforward, as LVLP sprayers work best with thinner paints, ensuring smooth, even coverage without clogging. Additionally, their energy-efficient operation helps minimize waste and airborne pollutants, making them a more environmentally friendly choice. Their compatibility with regulated air pressure systems also contributes to consistent spray quality. Using LVLP sprayers can also maximize efficiency by reducing paint consumption and overspray. To maximize their advantages, consider these points: efficient resource use. These features make LVLP sprayers perfect for fine details in craft, furniture, or automotive work, especially when aiming for precision application.

Comparing Performance: Coverage, Speed, and Finish Quality

When comparing sprayers, it’s essential to take into account how well they cover surfaces, how quickly they work, and the quality of the finish they produce. Airless sprayers typically offer high coverage and speed, making them ideal for large projects, but they can be bulky, affecting sprayer portability. HVLP sprayers provide a smoother finish with less overspray, often at a moderate speed, and tend to operate with lower noise levels, enhancing comfort during use. LVLP sprayers excel in detailed work, offering good coverage with precise control, though they may be slower. Your choice depends on your project’s scale and desired finish—if speed matters, airless is faster; if finesse and quieter operation are priorities, HVLP or LVLP might suit better.

Ideal Projects and Applications for Each Sprayer Type

Each sprayer type is best suited for specific projects based on their strengths and limitations. If you’re working on decorative finishes, LVLP sprayers excel with detail work and thin coatings, making them ideal for furniture or cabinetry. HVLP sprayers are versatile for both decorative finishes and light to medium industrial coatings, providing a smooth, professional look with minimal overspray. Airless sprayers handle large-scale projects efficiently, perfect for extensive industrial coatings or exterior siding. Consider these points:

- Use LVLP for intricate detail work and thin materials

- HVLP is great for smooth finishes on furniture and appliances

- Airless sprayers are best for large, fast coverage areas

- Choose based on project size, desired finish, and coating type

Matching the sprayer to your project ensures quality results and efficiency.

Factors to Consider When Choosing a Sprayer

Choosing the right sprayer depends on several key factors tailored to your project’s needs. First, consider the paint color and finish you desire, as different sprayers handle detail and coverage differently. Environmental impact also plays a role; some sprayers produce less overspray and waste, reducing pollution. Additionally, think about project size—airless sprayers cover large areas quickly, while HVLP and LVLP are better for detailed work. The table below highlights these factors:

| Factor | Best for | Environmental Impact |

|---|---|---|

| Paint color & finish | Fine detail or smooth coats | Less overspray, eco-friendly |

| Project size | Large surfaces | Lower waste with efficient use |

| Environmental impact | Eco-conscious projects | Reduced pollution |

| Ease of use | Beginners or quick jobs | Minimal overspray |

Matching these factors ensures you select the ideal sprayer for your project.

Maintenance, Cost, and Practical Tips for Optimal Use

Regular maintenance is essential to keep your sprayer functioning efficiently and extend its lifespan. To do this, regularly clean filters, nozzles, and hoses. Proper sprayer calibration ensures consistent results; always check and adjust settings before use. When storing your sprayer, use appropriate storage solutions to prevent damage and corrosion—preferably in a dry, covered area. Here are practical tips for maximum use:

- Clean after each use to prevent buildup

- Check and calibrate settings before starting projects

- Store in a dry, protected environment

- Replace worn parts promptly to maintain performance

Investing in quality storage solutions and routine maintenance saves you money and time, keeps your sprayer in top condition, and ensures professional results every time.

Frequently Asked Questions

Which Sprayer Type Is Best for Outdoor Furniture Projects?

For outdoor furniture projects, an airless sprayer is your best choice. It provides fast coverage and handles thick paints well. Just remember, proper sprayer maintenance is key to keep it running smoothly, and you should check paint compatibility to avoid clogs or uneven finishes. This way, you’ll achieve a smooth, professional-looking coat quickly and efficiently, making your outdoor furniture look great and last longer.

How Do I Prevent Overspray With Each Sprayer Type?

To prevent overspray with each sprayer, you should focus on spray pattern adjustment and distance control. For airless sprayers, keep a consistent distance and reduce pressure to minimize overspray. With HVLP and LVLP sprayers, adjust the spray pattern for a smaller, more controlled application, and hold the spray gun closer to the surface. Practicing steady movements and maintaining proper distance helps guarantee a smooth, overspray-free finish.

Are There Safety Concerns Specific to Each Sprayer?

Think of safety as your shield in a battle with paint. Each sprayer type has its own hazards, so you need to gear up with protective gear like masks and goggles. Ventilation considerations are vital, too, ensuring airborne fumes don’t turn into enemies. Follow manufacturer instructions carefully, stay alert, and create a safe workspace. This way, you protect yourself while turning your project into a masterpiece.

Can I Use the Same Paint or Stain in All Sprayers?

You might wonder if you can use the same paint or stain in all sprayers. While some paints are versatile, paint compatibility and stain suitability vary with sprayer types. Always check the product labels for compatibility, as thicker paints may clog fine sprayers like HVLP or LVLP. For best results and to avoid damage, use the recommended materials suited specifically for each sprayer.

Which Sprayer Offers the Most Precise Control for Detailed Work?

Coincidence often brings you to the right tool for precise work. For detailed craftsmanship, HVLP sprayers offer the most accurate control, thanks to their lower pressure and fine spray pattern. This sprayer accuracy lets you achieve intricate finishes with ease. If you’re focused on precision, HVLP is your best choice, helping you master detailed projects without overspray or loss of control.

Conclusion

Choosing the right sprayer is like picking the perfect tool for your craft—each has its own strengths and quirks. Whether you need the power of airless, the precision of HVLP, or the efficiency of LVLP, understanding their differences helps you make smarter decisions. When you match the sprayer to your project, you’re not just spraying paint—you’re shaping your vision. So, pick wisely, and let your projects flourish like a garden in full bloom.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.