Understanding paint sprayer filters is key to maintaining smooth spray performance and preventing issues. You’ll find different types, like mesh and foam filters, each suited for specific projects. Regularly checking and cleaning filters helps avoid clogs, uneven spray, and damage, prolonging your equipment’s life. Proper installation and maintenance are essential for consistent results. Keep exploring to discover how to choose, install, and extend the lifespan of your filters effectively.

Key Takeaways

- Filters remove debris and impurities, ensuring consistent spray quality and preventing equipment clogs.

- Common filter types include mesh, foam, and cartridge, selected based on paint viscosity and project needs.

- Proper installation and regular inspection help identify signs of clogging or damage, maintaining optimal performance.

- Regular cleaning, correct storage, and timely replacement extend filter lifespan and ensure professional spray results.

- Troubleshooting involves checking for leaks, debris, and flow issues, with maintenance preventing costly repairs.

The Purpose of Paint Sprayer Filters

Paint sprayer filters are essential components that guarantee your painting process runs smoothly. Their main purpose is to improve paint quality by removing debris and impurities that could clog the nozzle or cause uneven coverage. When filters are in place, you’ll notice a significant boost in spray consistency, making your application more uniform and professional-looking. By trapping particles, filters prevent clogs and splatters, reducing the need for rework. This ensures your paint flows smoothly through the sprayer, giving you better control and a cleaner finish. Using quality filters also extends the life of your equipment, saving you money and time. Regular maintenance, including replacing filters when necessary, is crucial for optimal performance. Proper filter selection and upkeep can also help prevent clogging issues, which are common without effective filtration. Additionally, understanding AI Security can help in developing better monitoring systems for maintaining equipment and safety standards. Overall, filters are crucial for achieving a flawless, high-quality paint job while maintaining efficient, consistent spray performance. Incorporating filter maintenance best practices can further enhance your results and prolong the lifespan of your sprayer. Regularly inspecting and cleaning filters can also prevent airflow restrictions, ensuring your sprayer operates at peak efficiency.

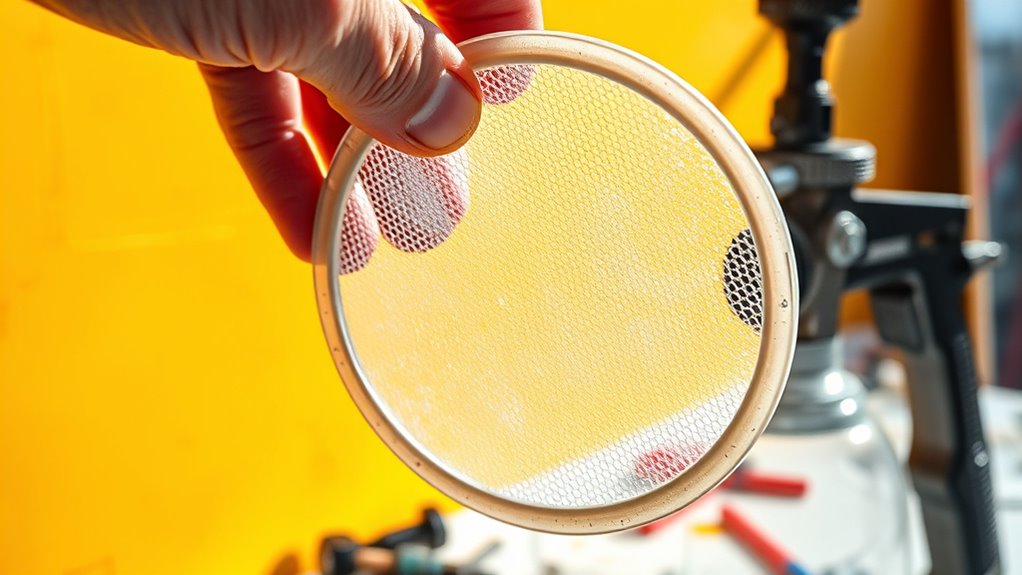

Different Types of Paint Sprayer Filters

To guarantee your sprayer performs at its best, it’s important to understand the different types of filters available. You’ll find various types of mesh filters, which use fine metal or nylon screens to trap debris and prevent clogs. These mesh filters come in different mesh sizes, offering options for different paint viscosities and project needs. Additionally, foam filter varieties are common, made from porous foam that captures larger particles while allowing paint to flow smoothly. Foam filters are easy to clean and replace, making maintenance straightforward. Both types of filters help assure a consistent spray pattern and protect your equipment. Proper filter maintenance is essential for preventing damage and ensuring a smooth, high-quality finish. Regular inspection and cleaning of filters help maintain optimal paint flow and prolong the lifespan of your sprayer. Using the appropriate filter type based on your project requirements can also enhance overall sprayer efficiency, which is crucial for achieving professional results. Being aware of filter types and their specific functions helps optimize your painting process and avoid costly repairs.

How to Choose the Right Filter for Your Project

Choosing the right filter for your project depends on understanding your specific needs and the type of material you’ll be spraying. First, consider the filter material; some filters are made from nylon, polyester, or stainless steel, each suited for different substances. For example, stainless steel filters work well with thicker paints and solvents, offering durability and easy cleaning. Next, assess the filter size; finer filters (smaller micron ratings) are ideal for smooth finishes and detailed work, while larger pore sizes suit thicker, more viscous paints. Matching the filter size to your project ensures proper flow and prevents clogs. Additionally, considering the filter’s compatibility with various AI security solutions can help ensure you select a filter that aligns with your project’s specific requirements. Being aware of health benefits related to proper equipment maintenance can also contribute to safer and healthier working conditions. Regular inspection and replacement of filters prevent contamination and maintain optimal spray quality, enhancing overall safety. By selecting appropriate filter material and size, you optimize your spray quality and reduce maintenance, making your project smoother and more efficient.

Step-by-Step Guide to Installing Filters

Installing filters correctly is essential for ensuring smooth spraying and preventing clogs. First, identify the filter type compatible with your sprayer—whether it’s a mesh, cartridge, or inline filter. Before installation, turn off your sprayer and relieve pressure. Remove the spray gun or hose connection, then carefully detach the old filter if present. Next, insert the new filter, ensuring it fits securely and aligns properly with the designated slots or connections. Follow the specific installation steps for your filter type: tighten fittings without over-tightening, and double-check that the filter is seated correctly. Reattach the hose or spray gun, turn the sprayer back on, and test for leaks. Proper installation of the right filter type ensures ideal performance and reduces maintenance issues. Additionally, understanding the different filter types helps in selecting the best option for your specific spraying needs.

Signs That Your Filter Needs Cleaning or Replacement

If your spray pattern becomes uneven or you notice spots missing paint, your filter might be clogged. Visible blockages or debris on the filter indicate it’s time to clean or replace it. Addressing these signs promptly keeps your sprayer working smoothly and guarantees a quality finish. Regular maintenance can prevent more serious issues and extend the lifespan of your equipment through proper cleaning techniques. Additionally, understanding different filter types helps in selecting the right replacement to suit your specific spraying needs. Recognizing the science of sound healing can also inform how you incorporate sound vibrations for relaxation during long projects. For added protection, consider using vetted 1st home theatre projectors that maintain optimal performance over time. Being aware of nutritional sources like acorn bread can inspire sustainable practices and resourcefulness in various projects.

Reduced Spray Performance

When your paint sprayer starts delivering uneven or sputtering spray patterns, it’s often a sign that the filter is clogged or dirty. A restricted filter can disrupt the paint consistency, causing inconsistent flow and poor atomization. This can lead to reduced spray performance, which affects the overall quality of your paint job. You might notice the spray nozzle sputters or pulsates, indicating reduced performance. If you’re applying a smooth, even coat, but the spray feels inconsistent, it’s time to check the filter. A dirty filter limits the flow of paint, forcing the sprayer to work harder and potentially affecting spray quality. Regularly inspecting and cleaning or replacing your filter helps maintain ideal spray performance and ensures your paint application remains smooth and even. Additionally, understanding the importance of filter maintenance can help prevent these issues before they start. Proper filter cleaning tools can make this process quicker and more effective, prolonging the life of your sprayer and maintaining optimal spray quality.

Visible Filter Blockages

Visible blockages in your filter are clear signs it needs immediate attention. If you notice debris or buildup during visual inspection, it indicates filter clogging, which can hinder spray quality. Regularly check your filter for signs of dirt or obstructions, especially if your sprayer’s performance drops or the spray pattern becomes uneven. A clogged filter restricts the flow of paint, leading to uneven coverage and potential damage to your equipment. Conducting a quick visual inspection before each use helps catch these issues early. If you see visible dirt or buildup blocking the filter openings, it’s time to clean or replace the filter to restore proper airflow. Proper filter maintenance and timely cleaning are essential for optimal performance. Staying attentive to filter clogging ensures your sprayer operates smoothly and produces a professional finish.

Best Practices for Maintaining Paint Sprayer Filters

Maintaining your paint sprayer filters is essential for ensuring smooth application and preventing clogs. Start by regularly inspecting the filter for paint sprayer contaminants like dried paint, debris, or overspray buildup. Clean the filter promptly when you notice any buildup to maintain proper flow. When selecting filter material, choose a type compatible with your paint and sprayer to prevent damage and ensure effective filtration. Always follow the manufacturer’s cleaning instructions, which typically involve rinsing with water or solvent, and avoid harsh abrasives that could damage the filter. Reinstall the filter securely after cleaning to avoid leaks. Proper maintenance reduces strain on your sprayer and extends filter lifespan, leading to better spray quality and fewer interruptions during projects. Regular use of appropriate filter types can also improve overall spray performance and longevity of your equipment.

Troubleshooting Common Filter-Related Issues

When your paint sprayer isn’t performing properly, the first step is to check for clogged filters, which can restrict flow and cause uneven spraying. If you notice leaks around the filter area, it’s time to inspect and fix any loose fittings or damaged seals. Addressing these common issues promptly helps keep your sprayer working smoothly and efficiently.

Identifying Clogged Filters

Clogged filters are a common cause of spray gun issues, and recognizing the signs early can save you time and frustration. When filter clogging occurs, you’ll notice uneven spray patterns, reduced flow, or sputtering from the gun. You might also see paint splattering or dripping, indicating debris buildup blocking the filter. If the spray feels weaker or inconsistent, it’s likely the filter is blocked. Regularly inspect the filter for visible debris or paint residue. When you remove the filter, check for obstructions or buildup that restricts flow. Addressing these signs promptly prevents further issues and keeps your sprayer functioning smoothly. Keeping an eye on filter condition helps you identify clogging early, ensuring peak performance and a quality finish.

Resolving Filter Leaks

Filter leaks can disrupt your spraying process and lead to messes or wasted material. To resolve leaks, start by inspecting the filter sealant around the filter housing. If you notice gaps or cracks, replace the sealant with a new, high-quality gasket or O-ring designed for leak prevention. Guarantee the filter is seated properly and tightened securely, but avoid over-tightening, which can damage the seal. Check for any cracks or warping in the filter or housing that might cause leaks. Applying a fresh layer of filter sealant can also help improve the seal and prevent future issues. Regularly maintaining and inspecting your filters ensures a tight fit and reduces the risk of leaks, helping you achieve smooth, efficient spray jobs.

Tips to Extend the Life of Your Paint Sprayer Filters

To get the most out of your paint sprayer filters, regular maintenance and proper cleaning are essential. Start by thoroughly cleaning your filters after each use; filter cleaning prevents buildup and clogs that can reduce efficiency. When cleaning, use the right cleaning solution and avoid harsh brushes that might damage the filter material. Proper filter storage is equally important; keep filters in a clean, dry place away from direct sunlight to prevent deterioration. Store them in a sealed container or protective bag to prevent dust and debris from settling on the filter surface. By consistently cleaning and storing your filters correctly, you’ll extend their lifespan, maintain ideal spray quality, and save money on replacements.

Frequently Asked Questions

Can I Use Generic Filters Instead of Manufacturer-Specific Ones?

You might wonder if generic filters work instead of manufacturer-specific ones. While they may seem compatible, filter compatibility isn’t guaranteed, and using the wrong filter can reduce filter effectiveness. Always check if the generic filter fits your sprayer and maintains proper filtration. If it doesn’t, it could cause clogs or damage, so it’s safer to stick with the recommended filters for peak performance and protection.

How Often Should I Replace Filters During a Large Project?

Think of your filter as the heartbeat of your project. During a large project, you should substitute filters regularly, typically every few hours or after every 10-15 gallons sprayed, depending on filter lifespan and project duration. Keep a close eye on spray quality; if you notice sputtering or uneven coverage, it’s time for a change. Regular replacements ensure consistent results and prolong your equipment’s life.

Are There Eco-Friendly Options for Paint Sprayer Filters?

You’re wondering if eco-friendly paint sprayer filters exist. Yes, there are biodegradable filters made from natural materials that break down faster in the environment. Additionally, you can find filters made from recycled materials, reducing waste. These options help you stay eco-conscious without sacrificing performance. Just verify you check product labels and manufacturer info to confirm their sustainability claims, making your project greener and more responsible.

What Safety Precautions Should I Take When Handling Used Filters?

When handling used filters, you should always wear personal protective equipment like gloves and a mask to avoid contact with paint residues. Make sure to handle filters carefully to prevent spills or dust dispersal. Proper disposal is essential; check local regulations for hazardous waste. Dispose of filters in designated containers and never throw them in regular trash. These precautions keep you safe and protect the environment.

How Do Filters Affect the Overall Finish Quality of My Paint Job?

You want a flawless paint finish and consistent spray, so filters play a vital role. They trap debris, preventing imperfections, and guarantee smooth, even spray flow. When filters are clean and properly maintained, your paint job looks smooth, with no runs or uneven spots. Dirty or clogged filters compromise spray consistency, leading to rough textures and uneven finishes. Keep filters in top shape to achieve professional, high-quality results every time.

Conclusion

Did you know that regular filter maintenance can extend your paint sprayer’s lifespan by up to 30%? By understanding the different types, how to choose, and maintain your filters, you’ll guarantee smooth, professional results every time. Staying on top of cleaning and replacement not only saves you money but also prevents costly clogs and inconsistencies. Keep your sprayer in top shape, and enjoy flawless projects with less hassle and more confidence.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.