HVLP turbine guns generate air through a turbine system, offering low-pressure, fine atomization ideal for detailed finishes and precision work. Compressor spray guns rely on external compressors, providing higher airflow and pressure for larger surfaces and thicker coatings. HVLP systems are portable, quieter, and better for smaller projects, while compressor guns are more powerful but less portable. To find out which fits your needs best, explore more details below.

Key Takeaways

- HVLP turbines generate air using internal turbines, offering low-pressure, high-volume spray ideal for detailed finishes, while compressor guns rely on external compressors for higher pressure output.

- HVLP systems are portable, quiet, and suited for precision work; compressor guns provide higher airflow for larger-scale projects and thicker coatings.

- HVLP guns produce minimal overspray and waste, making them environmentally friendly; compressor guns are better for heavy-duty, broad coverage applications.

- Maintenance for HVLP turbines is simpler with fewer moving parts, whereas compressor guns require regular cleaning of nozzles and filters due to higher pressure operation.

- Cost-wise, HVLP turbines often have a higher initial price but can save money long-term through reduced material waste and easier upkeep.

How HVLP Turbine and Compressor Spray Guns Work

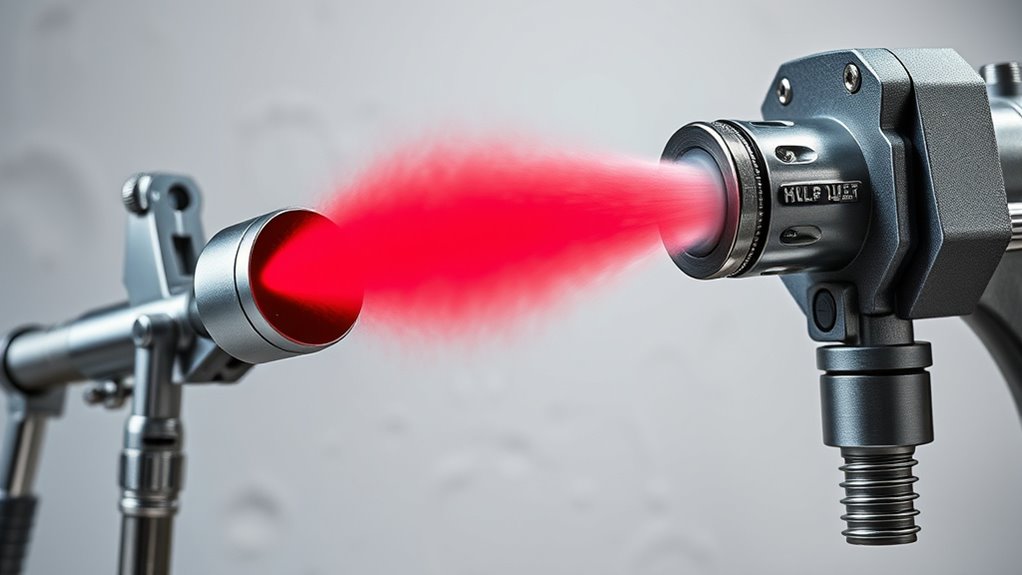

HVLP turbine and compressor spray guns work by forcing air through a nozzle to atomize paint or coatings, creating a fine spray that results in a smooth finish. This process heightens finish quality by producing an even, consistent layer of paint, reducing overspray and waste. With HVLP turbines, air is generated by a turbine system, offering a portable and quiet operation that’s ideal for precise work like color matching. Compressor spray guns rely on an external compressor to deliver pressurized air, often providing higher airflow for larger projects. Both types allow you to control spray patterns and flow, critical for achieving accurate color matching. Their ability to produce a controlled, fine spray ensures your finish is smooth and professional-looking, making them essential tools for detailed or high-quality paint jobs. Additionally, understanding the contrast ratio of your equipment can help optimize the visual results of your painted finishes, and choosing the right air pressure can significantly impact the application quality. Considering airflow capacity is also important to match your spray gun to the size and scope of your project, ensuring optimal performance and finish quality. Properly maintaining and adjusting these parameters can further enhance the spray efficiency and overall outcomes of your painting tasks. Proper equipment maintenance is crucial for sustained performance and achieving the best possible finish.

Key Features and Technology Differences

While both HVLP turbine and compressor spray guns produce fine, controlled sprays, they differ markedly in their key features and underlying technology. HVLP turbines rely on a high volume of air at low pressure, which delivers a gentle, consistent spray ideal for achieving a smooth, high-quality paint finish. They often have a larger, more portable design and are energy-efficient. In contrast, compressor spray guns use an external compressor to generate higher pressure, resulting in a more forceful spray pattern suited for thicker coatings and larger surfaces. The key difference lies in their spray pattern control and paint atomization. HVLP guns produce a softer, more even spray, while compressor guns offer greater versatility with adjustable pressure for different paint types and finishes. Additionally, HVLP systems typically utilize specific types of nozzles designed for optimal atomization at low pressure. Proper maintenance of these systems, including filtration and pump protection, is essential to ensure consistent performance and quality results. Regularly inspecting and cleaning air filtration systems can help maintain optimal spray quality and prolong the lifespan of your equipment. Furthermore, understanding the technology differences can help users select the appropriate system for their specific painting needs. An awareness of these distinctions can also guide proper maintenance practices, ensuring longevity and optimal spray performance.

Ideal Applications for Each Type

Choosing the right spray gun depends on the specific project and application. HVLP turbine guns excel for fine finishing techniques, offering smooth, even coats ideal for furniture, automotive detailing, and delicate artwork. They are also environmentally friendly due to lower overspray and reduced waste. Additionally, their lower air volume helps minimize material waste and ensures a more controlled application, making them suitable for detailed work. Compressor spray guns are better suited for large-scale projects like industrial coatings or heavy-duty primer applications, where speed and power matter. They handle thicker materials and broader coverage efficiently. Consider these applications:

- Fine furniture finishing

- Automotive touch-ups

- Artistic or decorative work

- Large-scale industrial coatings

- Heavy-duty primer applications

Additionally, the choice between these spray guns can influence performance consistency, ensuring your project outcomes meet professional standards while minimizing material waste. Matching the spray gun to your project guarantees ideal results and minimizes environmental impact, helping you achieve professional finishes with ease.

Cost and Maintenance Considerations

When comparing HVLP turbines and compressor spray guns, you’ll want to contemplate initial costs and ongoing expenses. The upfront price varies, and maintenance or repairs can add up over time. Understanding these costs helps you choose the option that fits your budget and keeps your equipment running smoothly. Additionally, considering refrigeration cycle efficiency can inform your decision-making process for selecting reliable and secure equipment. Regularly assessing performance durability can further ensure your investment remains effective and cost-efficient over the long term. Moreover, evaluating cost-effective operation can help optimize your overall maintenance and operational expenses. Factoring in long-term savings can also provide insight into how different systems perform over years of use, helping you make a more informed choice.

Initial Purchase Price

The initial purchase price of HVLP turbine spray guns is typically higher than that of compressor spray guns, mainly due to their advanced technology and design. While the upfront cost might seem steep, it offers benefits like superior paint finish and enhanced user safety. Consider these factors when evaluating costs:

- Better control over paint atomization

- Reduced overspray and material waste

- Lower long-term operational costs

- Easier maintenance and cleaning

- Improved safety features for users

Additionally, the versatility of hybrid bikes demonstrates how advanced features can lead to increased efficiency and performance, which parallels the benefits seen with HVLP turbines. Although the initial investment is higher, HVLP turbines often lead to a more consistent, high-quality paint finish. Plus, their user safety features can help prevent accidents and health issues. Additionally, cost efficiency over time can be achieved through reduced material waste and maintenance expenses. Understanding the long-term savings potential can help justify the higher upfront cost. Incorporating cost-benefit analysis can provide a clearer picture of the overall value. Moreover, considering the initial investment alongside potential savings can help you make a more informed decision. Weigh these aspects carefully to determine which spray gun aligns best with your project needs and budget.

Ongoing Maintenance Costs

While the higher initial cost of HVLP turbine spray guns can be justified by their advanced features, understanding their ongoing maintenance requirements is equally important. These guns typically require regular cleaning to maintain ideal paint quality, preventing clogs and ensuring consistent spray patterns. You’ll need to inspect and replace filters and check for wear on parts over time. Proper maintenance helps preserve the environmental impact by reducing overspray and paint waste, making your operation more eco-friendly. Unlike compressors, HVLP turbines often have fewer moving parts, which can lower long-term repair costs. Additionally, maintaining the spray gun properly can extend its lifespan and ensure continued high performance. Neglecting routine upkeep can lead to decreased performance and increased expenses down the line. Staying on top of maintenance ensures your spray gun remains efficient, environmentally conscious, and capable of delivering high-quality finishes. Regularly following manufacturer recommendations and preventative maintenance routines can further enhance the longevity and reliability of your equipment. Incorporating routine inspections can also help identify potential issues early before they become costly repairs.

Repair and Replacement

Repair and replacement costs for HVLP turbine spray guns tend to be lower over time because they have fewer moving parts than compressor systems. This simplicity reduces the likelihood of breakdowns, saving you money on repairs. Additionally, their durable design helps maintain consistent paint quality, which is essential for professional finishes. When considering environmental impact, HVLP guns typically produce less overspray and waste, leading to fewer replacements and less environmental harm. To keep your equipment in top shape, consider these points:

- Regularly clean filters and nozzles

- Use proper maintenance routines

- Replace worn-out seals promptly

- Store equipment in a dry environment

- Opt for quality replacement parts

Portability and Ease of Use

When choosing between HVLP turbines and compressor spray guns, portability plays a key role in your workflow. You’ll find that some models are lightweight and easy to carry, making on-the-go projects simpler, while others are bulkier. Additionally, user-friendly operation guarantees you can set up and start spraying quickly without a steep learning curve.

Portability of Equipment

Portability plays a crucial role when choosing between HVLP turbine and compressor spray guns, especially if you need to move your equipment frequently or work in different locations. A portable setup guarantees you can easily transport your sprayer without hassle. HVLP turbines often feature a lightweight design, making them ideal for on-the-go projects. Compressors, depending on their size, can be bulkier and heavier, limiting mobility. Consider these factors:

- Ease of carrying during setup

- Size and weight of the equipment

- Compatibility with carrying cases or carts

- Quick assembly and disassembly

- Suitability for remote or mobile work environments

Your choice should align with your work’s mobility requirements, ensuring you can operate efficiently wherever the job takes you.

User-Friendly Operation

Choosing a spray gun that’s easy to operate can substantially improve your workflow and reduce frustration. An ergonomic design guarantees comfort during extended use, minimizing fatigue and enhancing precision. User safety is also critical; features like secure grips and safety locks protect you during operation. When selecting between HVLP turbines and compressors, consider how simple it is to set up and maneuver each. Here’s a quick comparison:

| Feature | HVLP Turbine | Compressor |

|---|---|---|

| Ergonomic Design | Compact, lightweight, easy grip | Often bulkier, less ergonomic |

| Ease of Use | Intuitive controls, portable | More adjustments needed |

| User Safety | Safe, stable operation | Risks with air pressure |

Prioritize user-friendly features for a smoother, safer painting experience.

Which Spray Gun Is Right for Your Project

Selecting the right spray gun depends on your project’s specific needs and the type of finish you want to achieve. Consider factors like paint drying time, spray pattern, and control. If you need a fine, detailed finish, a turbine spray gun offers a consistent spray pattern with less overspray. For larger projects requiring quick coverage, a compressor spray gun provides higher pressure and faster application. Think about the material you’re using and the level of precision needed. Also, evaluate your experience level—some guns are more user-friendly than others. Ultimately, consider portability, noise levels, and your budget. Making the right choice ensures better paint drying, even coverage, and a professional-looking finish. Keep these points in mind to select the best gun for your project.

Frequently Asked Questions

Which Spray Gun Offers Better Paint Atomization Quality?

You’re wondering which spray gun delivers better paint atomization quality. Generally, HVLP turbine spray guns offer superior paint finish and spray consistency because they produce a finer, more controlled spray with less overspray. This results in a smoother surface and less paint waste. While compressor guns can generate higher pressure, they may compromise finish quality if not properly adjusted. For a high-quality, even paint job, HVLP turbines are often the better choice.

How Do Spray Pattern Sizes Compare Between HVLP Turbines and Compressors?

You might think spray pattern sizes are consistent, but nozzle size variability influences precision. HVLP turbines often produce wider, more uniform spray patterns for large surfaces, while compressor guns offer customizable sizes with adjustable nozzles for detailed work. This means, with the right nozzle, you can achieve higher spray pattern precision tailored to your project. Always consider your specific needs and nozzle options to optimize your spray pattern size effectively.

Are HVLP Turbines Quieter Than Compressor Spray Guns?

You’ll find that HVLP turbines are generally quieter than compressor spray guns, thanks to their lower noise levels during operation. This makes them more suitable for environments where noise is a concern. Plus, turbines are lightweight and portable, so you can easily move them around your workspace. If quiet operation and portability matter to you, an HVLP turbine is a solid choice over traditional compressor spray guns.

Can Both Types Handle Thick or Viscous Paints Effectively?

Both HVLP turbines and compressor spray guns can handle thick or viscous paints, but their performance depends on paint viscosity and fluid flow capabilities. HVLP turbines typically struggle with high-viscosity paints unless you use a thinner or adjust pressure settings, ensuring smooth fluid flow. Compressor guns often have more power to spray thicker paints directly, making them more suitable for viscous coatings. Adjust your equipment accordingly for ideal results.

Which Spray Gun Is More Suitable for Large-Scale Industrial Projects?

Imagine you’re painting a massive wall; efficiency matters. For large-scale industrial projects, a compressor spray gun often wins out due to its higher industrial capacity, allowing faster coverage and better viscosity control. Budget considerations also influence your choice—while HVLP turbines are quieter and more precise, they may struggle with volume. So, if speed and capacity are key, a compressor spray gun is your best bet.

Conclusion

Choosing between an HVLP turbine and compressor spray gun ultimately depends on your specific needs and preferences. While one might seem more straightforward, the other offers unique advantages that could subtly elevate your project. By considering factors like application, budget, and portability, you can find a tool that gently guides your work toward success. Trust your instincts, and remember—sometimes the quieter option might just be the one that helps you achieve your best finish.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.