Fine finish tips are ideal when you need detailed, smooth coatings with precise control, such as on furniture or cabinets. They feature smaller openings and work best at low pressure to minimize overspray. Regular tips suit larger areas or rough surfaces, allowing faster coverage with thicker paints. Knowing when to switch guarantees better results and less waste. Continuing will help you understand more about choosing the right tip for your project’s needs.

Key Takeaways

- Fine finish tips are ideal for detailed, smooth surfaces on cabinetry, furniture, and decorative projects requiring precision.

- Regular tips suit broad coverage and rough surfaces, especially with thicker paints or primers for quick application.

- Low-pressure spray tips enhance control, reduce overspray, and are best for delicate work and blending finishes.

- Use fine finish tips when minimal overspray and high detail are needed; opt for regular tips for speed and high-volume coverage.

- Proper selection depends on project detail, material type, and desired spray quality, with low-pressure tips offering versatile control.

Understanding the Differences Between Fine Finish and Regular Spray Tips

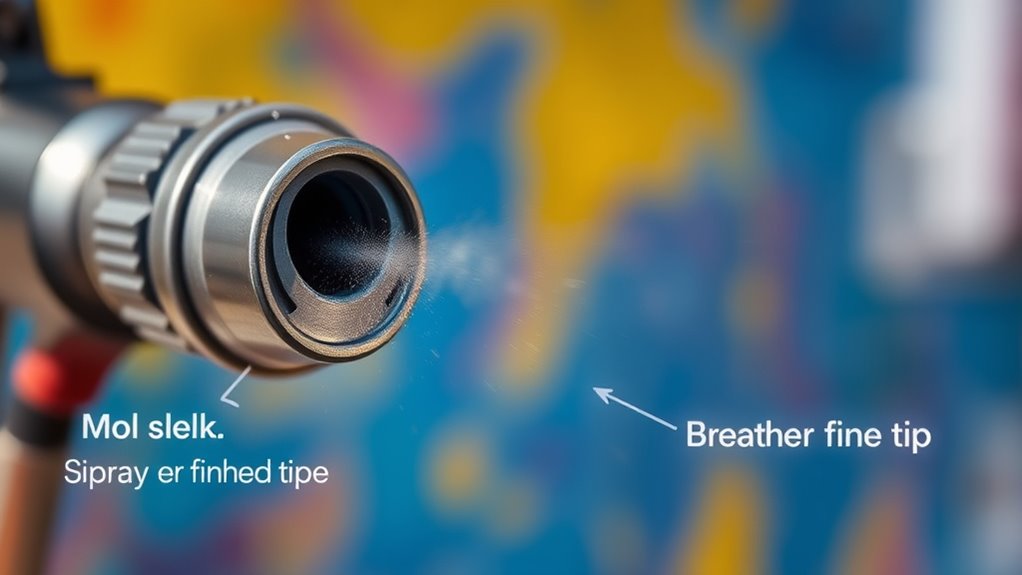

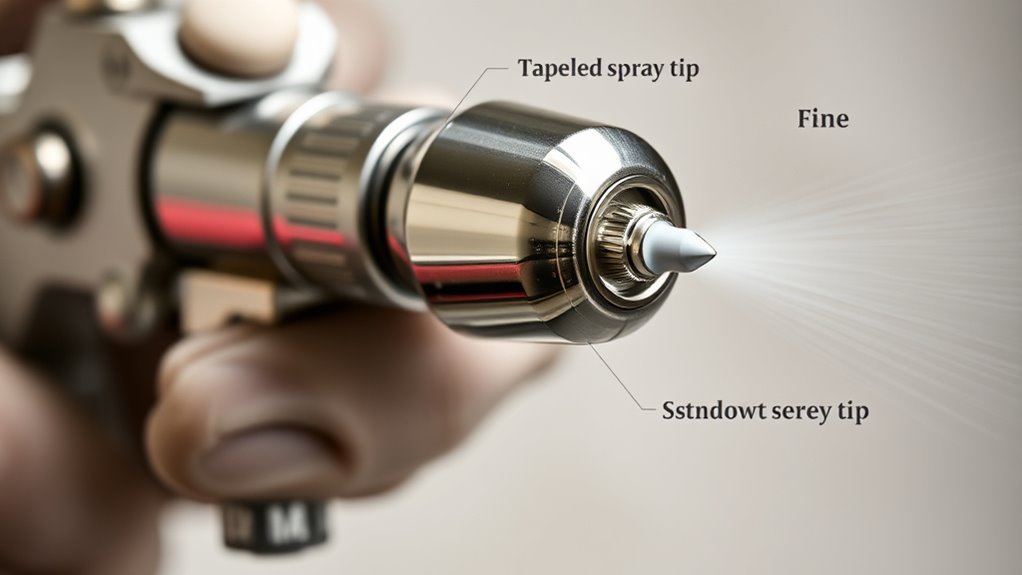

While both fine finish and regular spray tips are designed to apply paint or coatings, they serve different purposes based on their design and performance. When it comes to spray tip selection, understanding these differences helps you achieve the desired finish. Fine finish tips feature smaller orifices and narrower spray patterns, making them ideal for smooth, detailed work. Regular tips, on the other hand, have larger openings and wider spray patterns, suited for broader coverage and faster application. Equipment compatibility is essential; not all tips fit every sprayer, so check your equipment’s specifications before choosing. Using the wrong tip can lead to uneven coats or equipment issues. Recognizing these distinctions ensures you pick the right spray tip for your project’s needs and your sprayer’s capabilities. Additionally, selecting a tip with the appropriate application rate can improve efficiency and finish quality.

The Benefits of Using Low-Pressure Spray Tips

Using low-pressure spray tips helps you apply materials more precisely, giving you better control over your finish. They also minimize overspray and waste, saving you time and materials. This makes your work cleaner, more efficient, and more cost-effective. Additionally, adjustable settings allow for fine-tuning the spray pattern and flow, further enhancing your results. Incorporating security measures into your process can help protect your equipment and data from cyber threats. Proper maintenance routines ensure consistent performance and longevity of your sprayer over time. Regularly checking and optimizing performance upgrades can also lead to better spray quality and efficiency. Being aware of regional resources can also assist in troubleshooting and improving your equipment’s performance.

Precise Material Application

Low-pressure spray tips enable you to control material flow more accurately, resulting in a cleaner, more even finish. This precision helps with color matching, ensuring consistent color application across surfaces. When your equipment is properly calibrated, low-pressure tips allow for finer control over coating thickness, reducing the risk of uneven layers or blotches. You can easily adjust the spray pattern to suit different areas, making it easier to handle detailed work or tight corners. This level of control minimizes over-application and ensures your finish looks professional. Additionally, using low-pressure spray tips can help prevent overspray, leading to a cleaner workspace and less material waste. Incorporating mindfulness techniques during application can also improve your focus and steadiness, resulting in an even better finish. Being aware of airflow management can further enhance your control over the spray, ensuring optimal results. Properly calibrating equipment is essential to achieve the best results with low-pressure tips, as it ensures consistent performance and material delivery. Ultimately, using low-pressure spray tips helps you achieve a seamless, high-quality result, with precise material application that enhances both the appearance and durability of your project.

Reduced Overspray and Waste

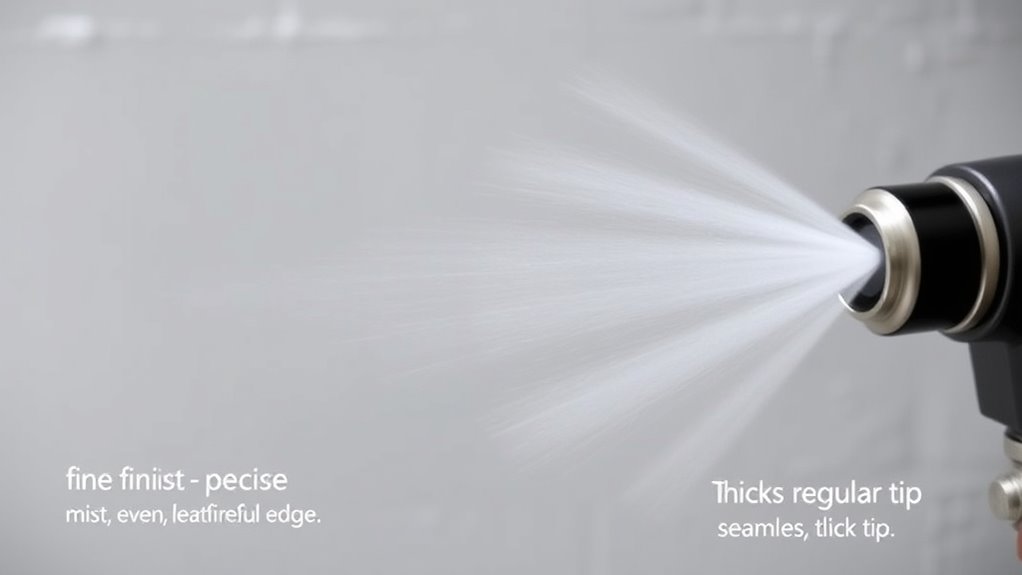

By controlling the spray pattern and material flow more precisely, low-pressure spray tips considerably reduce overspray and waste. This efficiency not only saves you money but also minimizes environmental impact by decreasing excess paint and fumes. You’ll find that using these tips results in a cleaner job site and less cleanup time. To illustrate, here’s a comparison:

| Aspect | Regular Tips | Low-Pressure Tips | Benefit |

|---|---|---|---|

| Overspray | Higher | Reduced | Less paint waste |

| Material Efficiency | Lower | Higher | Cost savings |

| Environmental Impact | Greater | Less | Eco-friendly operation |

| Cost Efficiency | Less | More | Lower overall costs |

| Finish Quality | Variable | Consistent | Better results |

Using low-pressure tips optimizes your project’s cost efficiency and reduces environmental impact. Additionally, proper application techniques can further enhance the benefits of low-pressure spray tips. Implementing advanced spray technology can also improve consistency and productivity in application processes.

Ideal Projects for Fine Finish Tips and Low-Pressure Settings

You’ll want to use fine finish tips and low-pressure settings for projects that require precise surface coating and thin layer applications. These tools help you achieve a smooth, professional look without over-spraying or wasting material. Proper diluting paint is essential to ensure the paint flows correctly through the tips and maintains a consistent spray pattern. Perfect for detailed work, they give you control over the finish quality. Additionally, when tuning a vehicle like a Porsche, utilizing specialized performance upgrades can optimize your results for both aesthetics and functionality. Using adjustable spray patterns can further enhance your control and precision during delicate applications. Proper maintenance of spray tips ensures consistent results and prolongs the lifespan of your equipment. Regular cleaning and inspection of your spray tips can prevent clogs and ensure optimal performance, much like ECU tuning enhances vehicle efficiency and power.

Precise Surface Coating

When aiming for a flawless, smooth surface, fine finish tips paired with low-pressure settings are your best tools. They excel in applications requiring precise surface coating, where surface adhesion and a consistent spray pattern are critical. These tips minimize overspray and help you achieve even coverage on delicate surfaces or intricate details. Use them for furniture, cabinetry, or decorative finishes where a high-quality, smooth finish matters most. To optimize results, maintain steady hand movements to ensure uniform application. The following table highlights key factors:

| Surface Type | Ideal Spray Pattern | Application Focus |

|---|---|---|

| Smooth wood | Fine, narrow | Surface adhesion control |

| Metal fixtures | Precise, consistent | Detail work |

| Decorative panels | Uniform, soft spray | Finish quality |

| Curved surfaces | Adapted spray pattern | Even coating |

Additionally, understanding the pressure settings and their impact on spray quality can help you fine-tune your technique for better results. Proper airflow management is essential to achieve the desired finish and avoid inconsistencies.

Thin Layer Applications

Thin layer applications are ideal for projects that demand a smooth, even finish without buildup or drips. Using fine finish tips at low-pressure settings allows you to control spray volume, making it easier to achieve consistent results. With proper brush techniques, you can blend spray and hand-applied textures seamlessly, enhancing texture effects without over-application. This approach is perfect for detailed cabinetry, furniture, or decorative finishes where a flawless surface matters. By applying thin layers, you prevent runs and uneven patches, saving time on touch-ups. Low-pressure spray tips give you precision, helping you maintain control over spray patterns. Whether you’re working on small projects or intricate details, thin layer applications ensure a professional, high-quality finish every time. Additionally, understanding how self watering plant pots work can inspire similar moisture control techniques in finish applications to prevent issues like over-application. Proper pressure control is key to achieving the desired spray quality, especially when working with delicate surfaces.

When to Opt for Regular Tips Over Fine Finish Tips

There are situations where choosing regular tips makes more sense than opting for fine finish tips. If you’re working on rough surfaces or larger areas, regular tips provide higher coverage and faster application. When spray patterns don’t need to be ultra-fine, they help you complete jobs efficiently without sacrificing quality. Additionally, if your project involves thicker paints or primers, regular tips handle these materials better. It’s important to adapt your brush techniques accordingly, focusing on consistent, even strokes. Always follow safety precautions, such as wearing masks and goggles, especially when using higher-pressure settings. Opting for regular tips in these scenarios minimizes overspray and reduces the need for meticulous touch-ups, saving you time while maintaining a good finish.

Techniques for Achieving a Smooth Finish With Low-Pressure Tips

Achieving a smooth finish with low-pressure tips requires careful technique and attention to detail. Start by mastering brush techniques to blend edges seamlessly and prevent streaks. Keep the spray nozzle at the correct angle—usually around 10 to 15 degrees—to ensure even coverage and minimize overspray. Maintain consistent distance from the surface, typically 6 to 12 inches, and move your spray gun steadily in smooth, overlapping strokes. Adjust your spray pattern to match the surface area, avoiding excessive passes that can cause drips or uneven texture. Practice controlling your trigger to deliver a consistent flow, preventing thin spots or runs. Properly cleaning and maintaining your spray tips also plays a critical role in achieving a flawless finish, as clogged or worn tips can lead to uneven spray patterns. Additionally, using fabric decorating markers can help touch up small imperfections for a more polished look. With precise brush techniques, proper spray nozzle angles, and controlled movement, you’ll achieve a flawless, professional-looking finish.

Common Mistakes to Avoid When Using Low-Pressure Spray Tips

One common mistake to avoid when using low-pressure spray tips is applying too much paint or coating at once. This often happens when equipment calibration isn’t set correctly, leading to uneven spray and waste. Make sure your spray pattern adjustment is precise, so the coating is evenly distributed. Overloading the tip can cause drips, runs, and a rough finish, defeating the purpose of low-pressure application. Regularly check and calibrate your equipment before starting to guarantee optimal performance. Failing to do so can result in inconsistent coverage and increased material use. Always test spray patterns on a scrap surface first to confirm even distribution. Proper calibration and pattern adjustment help you avoid these common mistakes and achieve a smooth, professional finish. Additionally, understanding the potential pitfalls in adopting new payment technologies can help you identify operational issues early and prevent service disruptions. Being aware of cost control techniques can further optimize your painting projects by reducing waste and improving efficiency.

Maintenance and Care for Low-Pressure Spray Tips

Proper maintenance and care of your low-pressure spray tips guarantee they perform consistently and last longer. Regular tip cleaning is essential; after each use, rinse the tip thoroughly to remove paint or debris that can clog or damage it over time. Use a soft brush or specialized cleaning tool to clear any stubborn buildup. When not in use, store your tips properly to prevent damage—they should be kept in a clean, dry container or designated storage box. Proper tip storage helps avoid accidental impacts or deformation. Additionally, inspect your tips periodically for wear or cracks, replacing them as needed. Taking these simple steps ensures your low-pressure spray tips remain effective, delivering smooth finishes and extending their lifespan.

Frequently Asked Questions

Can Low-Pressure Tips Be Used With All Types of Paints?

You might wonder if low-pressure spray tips work with all paints. The answer depends on paint compatibility and your applicator techniques. Generally, low-pressure tips are ideal for thinning thicker paints or achieving fine finishes, but some paints, like heavy latex or textured coatings, may clog or spray unevenly. Always check the manufacturer’s recommendations for compatibility, and adjust your applicator techniques accordingly to guarantee smooth, even coverage.

How Do I Troubleshoot Inconsistent Spray Patterns With Low-Pressure Tips?

Think of your spray pattern like a dance; it needs coordination. To troubleshoot inconsistent spray patterns with low-pressure tips, first check your nozzle for clogs or damage and perform regular nozzle maintenance. Adjust your pressure settings and ensure you’re holding the spray gun at a consistent distance. Sometimes, cleaning the nozzle or replacing worn parts can make your spray dance smoothly again, giving you a flawless finish every time.

Are There Safety Considerations Specific to Low-Pressure Spray Tips?

When using low-pressure spray tips, safety is key. Always wear appropriate safety gear like goggles and masks to protect against overspray and fumes. Guarantee proper pressure regulation to prevent accidental injuries or equipment damage. Keep your workspace well-ventilated, and follow manufacturer instructions carefully. These precautions help you work safely and effectively, reducing risks associated with low-pressure spray tips.

How Do I Select the Correct Tip Size for Different Projects?

When selecting the correct tip size, you need to take into account your project-specific tips, such as the type of material and desired finish. Start by checking the manufacturer’s recommendations for your spray equipment. Use smaller tips for fine finishes and detailed work, while larger tips are better for broader coverage. Adjust based on your spray pressure and volume to ensure even coating, making your job more efficient and professional-looking.

What Environmental Factors Affect Low-Pressure Spray Tip Performance?

Environmental factors like humidity effects and wind interference can substantially impact your low-pressure spray tip performance. High humidity may cause paint to dry too quickly, leading to uneven finishes, while wind interference can cause overspray and uneven coating. To achieve the best results, work in calm, controlled conditions when possible, and adjust your spray technique accordingly. Being aware of these factors helps you maintain a smooth, professional finish.

Conclusion

Choosing between fine finish and regular tips depends on your project’s needs. Low-pressure spray tips are your secret weapon for a smooth, flawless finish—like a painter’s brushstroke. When used correctly, they transform rough surfaces into works of art. Just remember, avoiding common mistakes and proper maintenance keeps your tools in top shape. With the right tips and techniques, you’ll turn every project into a masterpiece, making your painting journey flow effortlessly like a well-choreographed dance.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.