You should consider using a repair kit for your paint sprayer pump when you notice a drop in spray pressure, leaks, unusual noises, or frequent clogs. Worn seals, damaged valves, or cracks indicate that components are failing. Regular inspections help identify wear early before bigger issues develop. If you’re unsure whether repair is enough or a replacement is needed, further tips can help you determine the right approach—just keep going to discover more.

Key Takeaways

- Signs of reduced pressure, uneven spray, or sputtering indicate a rebuild or repair kit may be needed.

- Persistent leaks or pressure drops from seals or components suggest it’s time for repair.

- Unusual noises like grinding or knocking point to mechanical issues requiring a repair kit.

- Frequent clogs or priming difficulties signal that internal parts may need rebuilding.

- Visible cracks, damage, or worn seals and valves are clear signs to consider a repair kit.

Recognizing Decreased Spray Pressure and Flow

When your paint sprayer suddenly delivers less pressure and reduced flow, it’s a clear sign something’s wrong. You may notice uneven coverage or sputtering, which indicates a need for paint sprayer calibration. One common cause is changes in fluid viscosity; thicker paint or improper thinning can restrict flow and lower pressure. Before jumping to conclusions, check if the fluid’s viscosity aligns with the manufacturer’s recommendations. If it’s too thick, thinning the paint properly can restore pressure and flow. Also, ensure the spray settings are correct and that no obstructions are blocking the nozzle. Recognizing these issues early helps you determine if your pump needs a rebuild or if a simple adjustment will do. Proper calibration and fluid management are key to maintaining consistent spray performance. Additionally, understanding the benefits of airless paint sprayers can help you maintain optimal operation and avoid unnecessary repairs. Regularly inspecting the pump components can prevent costly damage and extend the lifespan of your equipment. Being aware of the key technology features in your sprayer can also assist in troubleshooting and improving overall efficiency. Incorporating routine maintenance practices can further enhance your troubleshooting skills and prolong your equipment’s life.

Signs of Leaks and Loss of Pressure

Leaks and a noticeable drop in pressure are clear signs your paint sprayer is compromised. You might notice paint dripping from connections or around seals, indicating that your paint sprayer accessories aren’t sealing properly. Loss of pressure can also manifest as uneven spray patterns or sputtering, which means your pump isn’t functioning efficiently. These issues often stem from worn-out seals or damaged components that require inspection and possibly replacing parts. Regular pump lubrication helps keep internal parts moving smoothly, reducing the risk of leaks and pressure loss. If you observe persistent leaks or pressure drops despite tightening connections, it’s time to contemplate a repair kit. Addressing these signs early prevents further damage and keeps your sprayer operating at peak performance. Additionally, proper maintenance can extend the lifespan of your equipment and prevent costly repairs. Being aware of the vulnerabilities and performing routine checks can help you avoid unexpected breakdowns, especially since recent AI discoveries have shown how technology can assist in troubleshooting complex equipment issues.

Unusual Noises During Operation

If your paint sprayer starts making strange noises during operation, it’s a sign something’s off. Pay attention to unusual sound patterns, like grinding or knocking, which can point to specific issues. Understanding these noises helps you identify their causes and determine the right fix.

Unusual Noise Patterns

Have you noticed any unusual noises coming from your paint sprayer pump during operation? These strange sounds can signal underlying issues, making pump noise analysis essential. Pay attention to irregular rattling, squealing, or grinding noises—each pattern can indicate specific problems. Recognizing these noise patterns helps you determine if your pump needs repair or a rebuild. Using a repair kit offers clear benefits: it can address worn-out seals, damaged pistons, or loose components causing the noise. Regularly monitoring sound patterns allows you to catch problems early, saving time and money. Addressing unusual noises promptly prevents further damage and extends your pump’s lifespan. Trust your ears as a valuable diagnostic tool—timely intervention keeps your sprayer running smoothly. Being aware of sound pattern variations can help you identify the exact issue before it worsens, especially since different noise types can point to specific pump component failures.

Causes of Strange Sounds

Unusual noises during operation often stem from specific mechanical issues within your paint sprayer pump. These sounds can signal problems that compromise pump efficiency and indicate the need for noise troubleshooting. Common causes include worn bearings, cavitation, or loose components. To identify the source, listen carefully for patterns or changes during use. Here’s a quick guide:

| Cause | Symptoms | Solution |

|---|---|---|

| Worn Bearings | Grinding or squealing | Replace bearings |

| Cavitation | Banging, knocking sounds | Check for blockages or leaks |

| Loose Parts | Rattling or vibrating | Tighten fittings or screws |

Addressing these issues promptly helps prevent further damage and maintains ideal pump efficiency. Regular maintenance practices can also help prevent these problems and extend the lifespan of your pump. Being aware of mechanical wear and how it impacts your equipment can help you better plan for repairs and replacements, ensuring optimal performance over time. Additionally, inspecting internal components regularly can help catch potential issues early before they lead to significant damage. Recognizing the signs of artificial deterioration can guide timely repairs and preserve the integrity of your equipment. Moreover, understanding the vibrational patterns associated with different issues can assist in more accurate troubleshooting.

Frequent Clogs and Difficulty in Priming

Frequent clogs and difficulty in priming are common issues that can hinder your paint sprayer’s performance. These problems often stem from paint chemistry, where improper mixing or thick formulations can cause blockages in the nozzle or intake. To prevent damage, always follow safety precautions, such as wearing gloves and masks, when working with different paint types. If you notice clogs happening regularly, it might be time to clean or replace filters, or consider adjusting your paint’s viscosity. Ensuring your paint is well-strained and properly thinned reduces the risk of clogs. When priming, make sure all connections are secure, and avoid forcing paint through if resistance is high. Regularly inspecting paint equipment and maintaining it properly can greatly extend its lifespan and performance. Additionally, implementing proper tuning techniques can help optimize your sprayer’s operation and minimize issues. Addressing these issues promptly keeps your sprayer running smoothly and extends its lifespan, especially when you understand the causes of clogs and how to troubleshoot them effectively. Performing routine maintenance on airless sprayer components can also help prevent frequent clogs and priming difficulties. Recognizing signs of wear and tear early can save time and prevent costly repairs.

Visual Inspection for Wear and Damage

Start by carefully inspecting the pump for any visible cracks or signs of damage. Check all connections and seals for leaks or wear that could affect performance. Addressing these issues early helps prevent more serious problems during reassembly. Additionally, ensure that the pump’s internal components, such as filters or membranes, are in good condition, as neglected parts can significantly impact the pump’s efficiency and longevity, especially when considering filter replacement indicators and proper maintenance. Recognizing wear patterns and lifestyle factors that contribute to equipment wear can also help in scheduling timely repairs and avoiding unexpected breakdowns. Monitoring maintenance schedules can further optimize equipment performance and prevent costly repairs. Incorporating data privacy considerations can further safeguard sensitive information during maintenance processes.

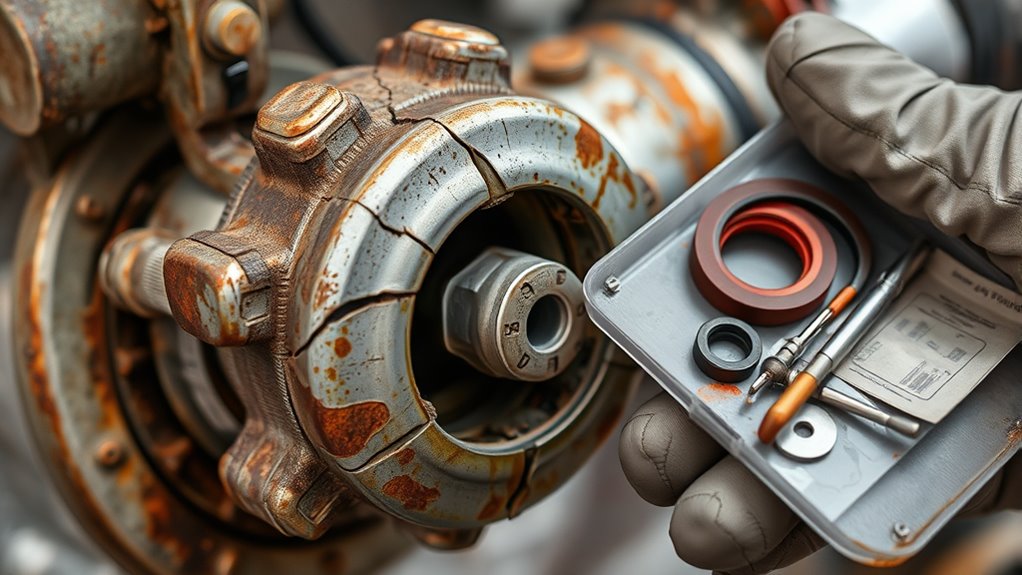

Identify Visible Cracks

How can you tell if your paint sprayer pump has sustained damage? One clear sign is visible cracks on the pump’s components. Carefully inspect the entire surface, paying close attention to seals, hoses, and fittings. Cracks may appear as thin lines or jagged splits, indicating weakened material. Since different paint sprayer brands use various materials, cracks might look different but are equally problematic. Always follow safety precautions, such as wearing gloves and eye protection, during inspection. Visible cracks can lead to leaks, reduced pressure, and pump failure if left unaddressed. If you spot any cracks, consider whether a repair kit is appropriate or if replacing parts is necessary. Regular visual inspection helps prevent bigger issues and keeps your sprayer functioning efficiently. Checking the integrity of seals and fittings regularly can also help prevent leaks and maintain optimal performance.

Check for Leaks

Since leaks can quickly undermine your paint sprayer’s performance, it’s essential to carefully inspect the pump and connected components for any signs of dripping or pooling. Look closely at seals, hoses, and fittings for any wet spots or residue. These leaks can reduce your paint sprayer efficiency and lead to uneven application. Regularly checking for leaks should be part of your pump maintenance schedule to prevent bigger issues down the line. If you notice any leaks, address them promptly by tightening fittings or replacing worn seals. Ignoring leaks can cause additional wear and damage, making repairs more costly. Staying vigilant with visual inspections ensures your pump operates smoothly and extends its lifespan, saving you time and money in the long run. Additionally, inspecting air leaks and ensuring proper sealing can further improve performance and prevent pressure drops.

Assessing the Condition of Pump Seals and Valves

To accurately assess the condition of pump seals and valves, you need to carefully inspect them for signs of wear, damage, or leakage. Look for seal degradation, such as cracks, brittleness, or hardening, which can cause leaks and reduce performance. Check the valves for deterioration, such as corrosion, pitting, or sticking, which can hinder proper operation. Feel for any unevenness or roughness that indicates wear. Leaks around seals suggest they’re compromised, requiring replacement. Deteriorated valves may not open or close fully, impacting flow and pressure. Regular inspection helps identify these issues early, preventing further damage. If you notice significant seal degradation or valve deterioration, it’s time to contemplate replacing these components to restore your pump’s efficiency.

Evaluating the Cost-Effectiveness of Repairs vs. Replacement

When deciding whether to repair or replace a paint sprayer pump, you need to carefully evaluate the costs and benefits of each option. Consider factors such as the age of your pump, repair costs, and the availability of paint sprayer accessories. If pump troubleshooting reveals minor issues, repairing might save money. However, if repairs are extensive, replacement could be more cost-effective. Think about:

- The cost of new pump parts versus a new unit

- Downtime during repairs vs. immediate replacement

- Long-term durability of repairs vs. new equipment

- Compatibility of repair parts with existing accessories

- Future maintenance expenses

Balancing these factors helps determine if fixing your pump is worth it or if investing in a new one makes more sense. This approach ensures your investment remains efficient and minimizes unexpected breakdowns.

The Benefits of Using a Repair Kit for Minor Issues

Using a repair kit for minor issues can be a cost-effective way to extend the life of your paint sprayer pump. By replacing small worn parts, you can restore proper pump function and maintain consistent paint mixture quality. A well-maintained pump ensures even spray patterns and prevents uneven application, saving you time and material costs. Additionally, using a repair kit supports environmental considerations by reducing waste—you’re avoiding the need to replace the entire unit prematurely. Repair kits often include essential components like seals and valves that keep your pump operating smoothly. This proactive approach minimizes downtime and keeps your project on schedule. Overall, a repair kit is a practical investment that promotes efficiency, sustainability, and peak performance for minor pump issues.

When to Consult a Professional for Pump Rebuilding

If your pump keeps malfunctioning despite your efforts, it’s time to contemplate professional help. Complex mechanical repairs or persistent performance issues often require specialized tools and expertise. Don’t hesitate to consult a pro if you’re unsure or if problems continue.

Persistent Performance Issues

Persistent performance issues with your paint sprayer pump can be a clear sign that professional intervention is necessary. If your spray pattern becomes uneven, paint flow slows, or you notice inconsistent atomization, it’s time to seek expert help. These problems often stem from wear or internal damage that affects your ability to maintain proper paint spray techniques and accurate paint mixing ratios. Ignoring these issues can lead to further damage and costly repairs.

Consider consulting a professional if you experience:

- Reduced spray pressure despite cleaning

- Clogged or uneven spray patterns

- Difficulty adjusting spray settings

- Frequent motor overheating

- Inconsistent paint flow during operation

Addressing these issues early ensures your pump operates smoothly and maintains high-quality results.

Complex Mechanical Repairs

When your paint sprayer pump shows signs of internal damage or complex mechanical issues, it’s time to bring in a professional. These problems often affect more than just performance—they can hinder accurate paint application, impacting tasks like paint sprayer calibration and spray pattern adjustment. Attempting repairs yourself might worsen the damage or lead to improper calibration, resulting in inconsistent coverage. A trained technician has the tools and expertise to diagnose and fix intricate issues, ensuring the pump functions smoothly. They can precisely realign internal components, optimize spray pattern adjustment, and restore consistent flow. If you notice irregular spray patterns, uneven coverage, or reduced pressure, don’t hesitate to seek professional help. Proper repair safeguards your equipment’s longevity and guarantees professional-quality results.

Preventative Maintenance Tips to Extend Pump Lifespan

Regularly inspecting and cleaning your paint sprayer pump is essential for preventing premature wear and ensuring reliable operation. Proper maintenance extends the lifespan of your pump and avoids costly repairs. Keep your equipment in top shape by:

- Using quality paint sprayer accessories to reduce strain on the pump

- Following effective pump lubrication techniques to prevent corrosion and friction

- Checking for clogs or debris that could impair performance

- Replacing worn seals and gaskets promptly

- Storing your sprayer in a clean, dry environment to prevent rust

Implementing these simple steps helps avoid unnecessary breakdowns. Regular cleaning and maintenance not only protect your investment but also ensure smoother operation. Stay proactive, and your pump will serve you reliably for years to come.

Frequently Asked Questions

How Often Should I Perform Maintenance on My Paint Sprayer Pump?

You should follow a regular maintenance schedule to keep your paint sprayer pump running smoothly. Typically, inspect and clean the pump after each use, especially if you’re using it frequently. For repair frequency, plan a more thorough check every few months or after heavy use. Promptly address any signs of wear or leaks, and don’t wait too long to perform maintenance, as neglecting it can lead to costly repairs.

What Are the Main Differences Between Repair Kits and Complete Pump Replacements?

The main differences between repair kits and complete pump overhauls lie in scope and cost. Repair kit advantages include targeting specific worn parts, saving money, and minimizing downtime. A complete pump overhaul, however, involves replacing the entire pump, ensuring maximum reliability but at a higher expense. Choose a repair kit when issues are limited, but opt for a full overhaul if your pump is heavily worn or failing to perform properly.

Can I Rebuild My Pump Myself Without Professional Tools or Skills?

Did you know that over 60% of DIYers successfully rebuild their paint sprayer pumps? You can definitely try it yourself with some basic DIY tips, but keep in mind, the right tool requirements are essential. If you lack experience or proper tools, it’s safer to consult a professional. Rebuilding a pump without skills might lead to further damage, so assess your comfort level before diving in.

How Do I Select the Right Repair Kit for My Specific Pump Model?

To select the right repair kit, you need to check your pump’s model compatibility first. Look for the model number on your pump or in the user manual. Then, compare the part specifications of the repair kit with your pump’s parts. Ensuring both match guarantees a proper fit and peak performance. Always choose a kit designed specifically for your model to avoid compatibility issues and maximize the longevity of your pump.

What Are the Long-Term Benefits of Regular Pump Maintenance and Repairs?

Regular pump maintenance and repairs bring you long-term benefits like extended lifespan and cost efficiency. By catching issues early, you prevent costly breakdowns and reduce downtime. Consistent upkeep keeps your equipment running smoothly, saving you money over time. You’ll experience fewer repairs, greater reliability, and improved performance. In the end, maintaining your pump isn’t just about fixing problems—it’s about protecting your investment and ensuring ideal results for years to come.

Conclusion

So, when your paint sprayer pump starts acting up, maybe it’s time for a repair kit—unless you enjoy the thrill of unexpected leaks and splatters. Remember, a little maintenance now can save you from costly replacements later. Or, if you’d rather turn your hobby into a guessing game, go ahead and ignore the warning signs. Your walls—and your patience—will thank you for choosing the smarter, more paint-friendly route.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.