To diagnose and fix air leaks in your paint sprayer system, start by inspecting all connections, hoses, and fittings for cracks, looseness, or damage. Use soapy water to spot bubbling at suspected leak points, and tighten fittings or replace damaged parts as needed. Conduct pressure tests to confirm leaks and systematically isolate problem areas. Regular maintenance and thorough inspections help prevent future issues. Keep going to discover more tips for a reliable, leak-free spray system.

Key Takeaways

- Perform visual inspections and use soapy water to identify leaks around fittings, hoses, and spray gun components.

- Conduct pressure tests with calibrated gauges to detect pressure drops indicating air leaks.

- Isolate system sections by disconnecting parts to pinpoint the leak source during testing.

- Apply soapy solution to suspect areas, watch for bubbling, and tighten or replace faulty fittings or seals.

- Maintain regular system checks and replace worn parts promptly to prevent future air leaks and ensure optimal spray performance.

Recognizing the Signs of Air Leaks in Your Paint Sprayer

Air leaks in your paint sprayer can be be subtle, but they often show clear signs if you know what to look for. You might notice inconsistent spray patterns or uneven paint distribution, which can be caused by leaks affecting spray gun calibration. Poor air compressor maintenance can lead to pressure drops, making the sprayer struggle to operate properly. Listen for hissing sounds that indicate escaping air, especially around connections or hoses. Additionally, increased overspray and paint mist outside the target area can signal leaks. Identifying these signs early helps prevent more significant issues and guarantees your sprayer performs effectively. Regularly checking for and addressing air leaks keeps your system calibrated, maintains consistent spray quality, and prolongs the equipment’s lifespan. Proper air pressure regulation is essential for optimal performance and preventing leaks from developing in the first place. Incorporating routine maintenance procedures can further help detect potential issues early and ensure your system operates efficiently, especially since proper filter replacement can improve airflow and reduce leak risks. Being aware of compressed air system issues can also help you troubleshoot and fix leaks more effectively. Additionally, using glycolic acid in your maintenance routine can help clean and remove buildup that might contribute to leak development, ensuring smoother operation.

Inspecting Key Components for Potential Leaks

To effectively detect leaks in your paint sprayer, you need to carefully inspect its key components, such as hoses, connections, and seals. Look for cracks, holes, or wear that could cause air escapes. Focus on areas where you’ve applied sealant, ensuring it’s intact and properly sealed. If you notice damaged parts or persistent leaks, consider component replacement to restore proper function. Additionally, check fittings and couplings for tightness and damage. Regular inspection helps prevent minor issues from escalating. Remember, sealing leaks effectively starts with thorough examination. Look for these signs:

Regularly inspect hoses, seals, and fittings for cracks, wear, or damage to prevent leaks and maintain optimal sprayer performance.

- Cracks or holes in hoses

- Worn or cracked seals

- Loose or damaged fittings

- Areas with old or deteriorated sealant

- Signs of corrosion or buildup around connections

- Understanding air leaks and their impact can help you identify and address issues more efficiently. Being aware of system components can further assist in pinpointing the source of leaks. Conducting routine system maintenance can also prolong the lifespan of your paint sprayer and ensure optimal performance. Incorporating proper sealing techniques can significantly reduce the likelihood of future leaks. Additionally, understanding the tuning of related equipment like Porsche vehicles emphasizes the importance of precise adjustments to maintain optimal system integrity.

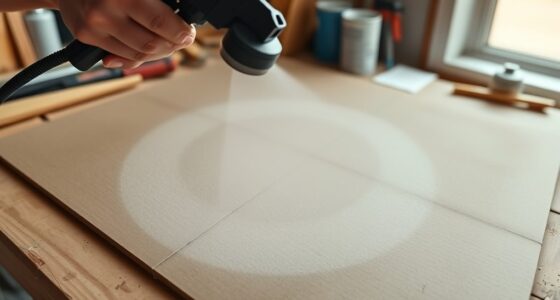

Using Soapy Water to Detect Air Escapes

To find air leaks, mix a soapy solution and apply it to your system’s connections. As you do, watch for the formation of bubbles, which indicate escaping air. This simple method helps you quickly identify problem areas that need fixing. Being aware of best oils for deep frying on keto can help you understand how to maintain healthy, low-carb options during troubleshooting. Additionally, inspecting airflow patterns can assist in pinpointing hidden leaks that may not be immediately visible. Recognizing the importance of eye patch benefits in skincare can also serve as a reminder of how targeted approaches can improve overall effectiveness. Remember, maintaining a strong father-daughter bond can also serve as a reminder of the importance of support and guidance in both personal relationships and technical repairs.

Prepare Soapy Solution

Before you begin inspecting for leaks, mix a soapy solution by combining a few drops of dish soap with water in a spray bottle or container. This simple mixture is essential for effective leak detection. Shake gently to create a uniform foam that will reveal air escapes. Be sure to use a clean spray bottle for accurate results. When applying the soapy solution, focus on connections, fittings, and hoses where leaks are most likely. Keep these tips in mind:

- Use fresh dish soap for better foam stability

- Avoid overly soapy mixtures to prevent excess residue

- Test the solution on a small area first

- Spray lightly to avoid washing away the foam

- Reapply as needed for thorough inspection

A properly prepared soapy solution makes leak detection quick and reliable, helping you identify issues early. Additionally, filter maintenance can help prevent the formation of leaks by ensuring your equipment remains in optimal condition. Regularly inspecting air pressure systems can also prevent leaks and prolong equipment lifespan.

Apply to Connections

Once your soapy solution is ready, focus on applying it directly to the connections, fittings, and hoses where air leaks are most likely. Use a brush or spray bottle to coat these areas thoroughly. As you do, watch for bubbling, which indicates escaping air. If bubbles form, you may need to tighten the connection or perform a seal replacement. Start by tightening any loose fittings carefully to minimize damage. If bubbles persist after tightening, inspect the seal or gasket for damage and replace it if necessary. Proper connection tightening ensures a tight seal, reducing air leaks. Seal replacement addresses worn or damaged components that can’t be fixed by tightening alone, restoring system integrity and preventing future leaks.

Observe for Bubbles

When inspecting for air leaks, applying a soapy water solution is an effective method. Spray or brush the solution onto suspect areas, then watch for air bubble formation. These bubbles indicate escaping air. Focus on the foam pattern analysis; irregular or continuous bubbling suggests a leak. Observe how the bubbles form and move—steady bubbles mean a minor leak, while rapid or persistent bubbles point to a more significant issue. Keep an eye on connections, hoses, and seals. Proper air quality maintenance and regular inspections are essential for optimal spray system performance. Look for small, consistent bubbles indicating slow leaks. Notice if bubbles are large or rapidly forming. Check for continuous bubbling around fittings. Examine areas where foam pattern analysis reveals irregular bubbles. Repeat the process after tightening fittings or adjusting components to verify fixes. Regular system testing helps prevent larger issues and ensures consistent spray quality.

Isolating the Leak Source With Systematic Testing

To pinpoint the leak, start with visual inspection to identify obvious cracks or loose fittings. Then, use pressure testing methods to detect drops in system pressure that indicate leaks. Additionally, identifying leak sources can be facilitated by listening for hissing sounds or using soapy water to observe bubble formation at potential leak points. Proper testing procedures and systematic approach can greatly improve accuracy in locating leaks. A comprehensive understanding of system components can help in diagnosing issues more effectively. Finally, isolate components one by one to confirm the exact source of the air escape. Effective filtration can prevent debris from causing leaks and ensure your equipment operates smoothly. Consulting product authenticity markers can also help ensure your equipment is genuine and functioning properly.

Visual Inspection Techniques

Identifying the exact location of an air leak in a paint sprayer system requires a systematic approach through visual inspection. Begin by examining connections, hoses, and fittings for cracks, looseness, or wear. Check the spray gun and nozzle for visible damage that may compromise air tightness. Ascertain your paint sprayer ergonomics allow easy access to all parts, making inspection smoother. Also, verify air compressor compatibility, confirming the pressure matches manufacturer specifications. Look for signs of oil or paint buildup around joints, which can indicate leaks. Use a flashlight to illuminate dark areas, and consider applying soapy water to suspected spots to spot bubbles. These techniques help you pinpoint leaks efficiently, saving time and preventing further damage. Additionally, understanding automated systems in your equipment can help you identify potential issues more quickly. Being aware of common pitfalls can also guide you in avoiding overlooked leaks during inspection. To enhance your detection process, consider inspecting the hose connections regularly, since worn or damaged hoses are common sources of leaks.

Pressure Testing Methods

Systematic pressure testing is an effective way to pinpoint the exact location of an air leak in your paint sprayer system. Begin by ensuring your pressure gauge calibration is accurate to get reliable readings. Connect leak detection tools, such as soapy water or ultrasonic detectors, to key points in the system. Gradually increase the pressure and monitor the gauge for drops, which indicate leaks. Focus on connections, fittings, and hoses, checking each component carefully. If you notice a sudden pressure loss, isolate that section and retest to narrow down the leak source. Consistent pressure readings confirm a sealed system, while fluctuations reveal leaks needing repair. This methodical approach saves time and prevents unnecessary disassembly, making leak detection precise and efficient.

Component Isolation Strategies

When tracking down an air leak in your paint sprayer system, isolating individual components is essential for pinpointing the exact source. Start by shutting off the system and systematically testing each part. Check hose tension to ensure hoses aren’t loose or cracked. Inspect and replace gaskets if they’re worn or damaged, as they often cause leaks. Disconnect sections one at a time to see if the leak stops, narrowing down the faulty component. Use soapy water on fittings and joints to identify bubbles indicating leaks. Consider gasket replacement in suspect areas and tighten hoses carefully to avoid unnecessary wear. This methodical approach helps you quickly identify whether a gasket, hose, or connection needs attention, saving time and preventing further damage.

Repairing Common Air Leak Issues Step-by-Step

To effectively repair common air leaks in your paint sprayer system, you need to follow a clear, step-by-step process. First, inspect all connections and hoses during paint sprayer maintenance, looking for cracks or loose fittings. Next, turn off the system and release pressure safely. Use soapy water to detect leaks around fittings, hoses, and the gun; bubbles indicate leaks. Tighten fittings or replace damaged hoses as needed. Check your air compressor troubleshooting guide if leaks persist, ensuring the compressor’s pressure is consistent. Reassemble everything securely and test the system by spraying onto a scrap surface. Consistent maintenance and careful inspection help prevent future leaks and ensure smooth operation, saving time and reducing paint wastage.

Preventative Measures to Avoid Future Leaks

Regular maintenance and careful inspection are key to preventing future air leaks in your paint sprayer system. By following consistent practices, you can catch issues early and prolong your equipment’s life. Proper storage is essential; store your sprayer in a clean, dry place to prevent damage and deterioration. Regular maintenance includes checking hoses, fittings, and seals for wear or cracks, and replacing worn parts promptly. Keep your equipment clean to avoid clogs that can cause pressure issues. Additionally, always follow manufacturer guidelines for assembly and storage. Consider creating a maintenance schedule to ensure routine inspections. Proper storage and diligent upkeep reduce the risk of leaks, saving you time and money while maintaining ideal spray performance.

Frequently Asked Questions

Can Air Leaks Affect Paint Quality and Finish Consistency?

Air leaks definitely influence your paint quality and finish consistency. When leaks occur, they disrupt the paint flow, causing uneven spray patterns. You might notice patchy coverage or drips, which compromise the final look. By addressing air leaks promptly, you’ll guarantee a steady paint flow and a uniform spray pattern, leading to a smoother, professional finish that meets your expectations every time.

What Safety Precautions Should I Take During Leak Repairs?

Thinking about leak repairs? It’s wise to prioritize safety. You should wear personal protective equipment like gloves and goggles to guard against potential irritants or splashes. Follow safe repair procedures by disconnecting the power source, venting pressure safely, and working in a well-ventilated area. Taking these precautions helps guarantee your safety while effectively fixing air leaks, minimizing risks, and keeping your workspace secure during maintenance.

Are There Specific Tools Recommended for Leak Detection?

You should use leak detection tools like ultrasonic leak detectors, soapy water solutions, or smoke pencils to spot leaks effectively. These tools help you pinpoint leaks quickly during inspection techniques, ensuring accurate detection. Ultrasonic detectors pick up high-frequency sounds, while soapy water bubbles reveal leaks visually. Smoke pencils create visible smoke, making it easier to identify even tiny leaks. Using these tools enhances your inspection process and helps you fix leaks efficiently.

How Often Should I Inspect My Paint Sprayer for Leaks?

Did you know that regular inspections can save up to 30% of your equipment costs? You should inspect your paint sprayer for leaks at least once a week during heavy use, and monthly when it’s less active. Consistent inspection frequency helps with leak prevention, ensuring your system runs efficiently and reducing costly downtime. Make this a routine to keep your sprayer in top shape and avoid unexpected failures.

Can Environmental Factors Cause or Worsen Air Leaks?

Environmental factors definitely impact air leaks in your paint sprayer system. Changes in temperature and humidity can cause materials to expand or contract, worsening existing leaks or creating new ones. Moisture interference can also compromise seals and fittings, making leaks more likely. You should regularly check your equipment, especially after weather shifts, as these environmental impacts can considerably affect the system’s performance and longevity.

Conclusion

Regularly inspecting your paint sprayer for air leaks can save you time and money. Did you know that unresolved leaks can reduce spray efficiency by up to 30%? By recognizing signs early and following proper repair steps, you guarantee peak performance and extend your equipment’s lifespan. Staying proactive with maintenance not only improves your results but also minimizes costly repairs. Keep your system leak-free to achieve the best finishes and keep your workflow smooth.

A seasoned painter with over 15 years in the industry, Mike transitioned from hands-on painting projects to the digital world of paint sprayers. His extensive experience gives him a unique perspective on what users truly need when it comes to painting tools. As the Editor in Chief of Paint Sprayer Zone, Mike ensures that every piece of content not only provides value but also reflects the realities of painting — the challenges, the joys, and the intricate details.